From Bottlenecks To Efficiency: Securing MRO Engine Ramp-Up And TaT

“Our analysis shows that aircraft engine MRO demand is likely to experience a near-term peak in 2026 and remain constrained through the end of the decade.”

— Jim Harris, Co-Leader of Bain’s global Aerospace and Defense practice

Bain&Company's latest survey confirms what many in the industry have long suspected: MRO demand will peak in 2026, but capacity shortages are already turning engine shops into bottlenecks.

For MRO leaders, reducing Turnaround Time (TaT) often depends on ensuring all parts are available at the kitting gate—a seemingly simple goal complicated by outdated, fragmented tools.

Let’s break down why MRO operations are more challenging than ever—and how leading teams are regaining control.

The Post-COVID Domino Effect: A Race That Keeps Getting Tougher

The aviation industry is still recovering from COVID-19, which grounded 60% of the global fleet and left MRO teams struggling to catch up. The impact has been severe:

- Deferred Maintenance Overload – Airlines delayed maintenance, leading to a 45% drop in MRO spending and a massive backlog.

- Emerging challenges caused by New Aircraft – While next-gen aircraft support sustainability goals, their engines require more repairs than expected, partly due to powder metal contamination.

- Supply Chain Disruptions – Parts suppliers can’t meet demand, forcing MROs to rely on scarce Used Serviceable Materials (USM) also chased by increasing pressure from OEMs.

Instead of recovering, MROs are now battling unpredictable lead times and severe part shortages.

Next-Generation Complexity: More Repairs, Fewer Certified Shops

The introduction of next-generation engines, such as CFM International’s LEAP and Pratt & Whitney’s GTF, has created new challenges:

- Higher-than-Expected Repair Rates – These engines demand more frequent servicing due to emerging failure modes.

- Diminishing Certified Shop Pool – New-gen engines require specialized accreditations, limiting the number of authorized MROs.

- Skills & Resource Strain – MROs must juggle both legacy and new-generation engines, stretching expertise and capacity to the limit.

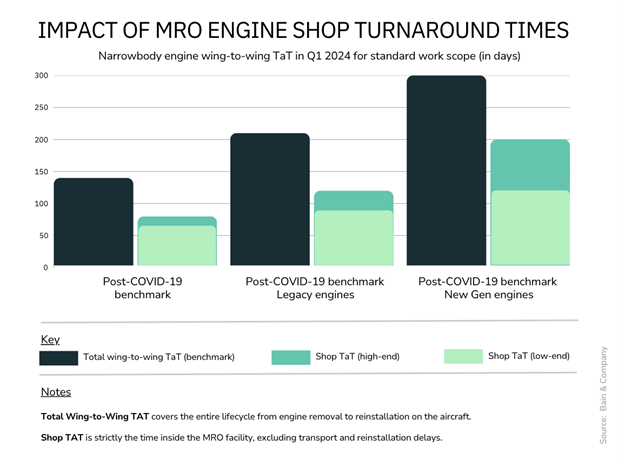

The result? Longer maintenance times.

Why MRO Teams Are Stuck in Firefighting Mode

Instead of using real-time insights to ensure the right parts arrive at the kitting gate on time, MRO teams spend up to 70% of their time manually chasing data—digging through spreadsheets, emails, and disconnected systems to track parts, capacity, and repair schedules.

This inefficiency leads to:

- Delayed maintenance completions

- Up to $10,000 in daily costs per immobilized engine

- Decreasing customer satisfaction

With so much time spent reacting instead of preventing issues, teams remain trapped in constant firefighting mode.

The Solution: Regaining Control with Pelico

At Pelico, we’ve spent the past two years partnering with leading MRO shops to develop a solution that reduces TaT and optimizes engine throughput.

With Pelico, MRO teams can:

- Reduce TaT – Identifying missing parts early enables MRO teams to prioritize critical repairs and streamline maintenance workflows, minimizing delays.

- Ensure Material Availability – Proactively addressing shortages enhances supply chain visibility, allowing teams to leverage alternatives like rotables and spare parts to keep operations running smoothly.

- Increase Engine Throughput – Optimizing shop capacity through strategic repair planning and alternative workflows ensures faster engine turnaround and improved efficiency.

- Make Smarter Resource Decisions – Balancing OEM and MRO priorities enables better allocation of new vs. used parts, optimizing both cost-effectiveness and availability.

The results speak for themselves;

- 40% reduction in TaT

- 94% increase in throughput

- 72% boost in team productivity

Your Next Step: Don’t Let Supply Chain Disruptions Ground Your MRO Operations

If your team still operates without real-time visibility, you’re running a marathon blindfolded. It’s time to take back control.

Pelico already helps MRO teams cut TaT by 40%. Schedule a demo today.