ZeroAvia has begun development of the 2-5-megawatt ZA2000 powertrain for 40-90-seat regional aircraft.

Hydrogen-electric propulsion startup ZeroAvia says it is prepared to supply Airbus with engines if the airframer decides to launch development of a zero-emission hydrogen-powered commercial aircraft under its ZEROe initiative.

“We hope to power their ZEROe,” ZeroAvia founder and CEO Val Miftakhov said at the Farnborough Airshow on July 22. Airbus is an investor in ZeroAvia and in May the companies partnered to study the creation of hydrogen hubs at Canada’s three largest airports.

“Airbus is testing technologies and ZeroAvia is one of the technology teams in their exploration,” Miftakhov said. “We hope to go on at least one of those [ZEROe] aircraft.”

Airbus is studying a hydrogen-electric concept with up to 100 passengers and up to 1,000-nm range as well as a hydrogen-combustion concept with 200 seats and up to 2,000-nm range. A propulsion down select is expected in 2026-27 and a launch decision in 2027-28.

ZeroAvia is likely talking to Airbus about an engine developed from its ZA2000 family, which has a planned power range from 2-5.4 megawatts to power regional turboprops and jets from 40-90 seats. “Airbus is an airframe manufacturer. We’re looking to supply engines to them,” he said.

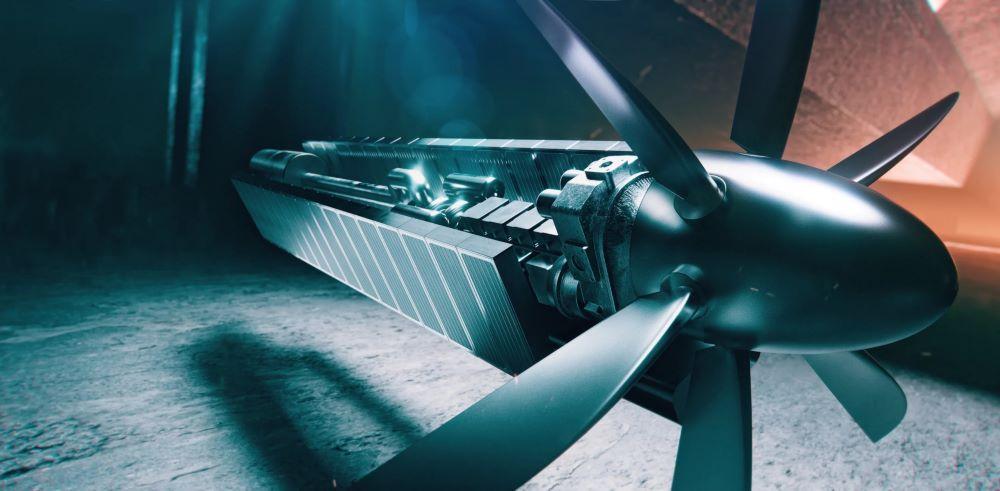

The ZA2000 uses high-temperature proton exchange membrane (HTPEM) fuel-cell technology that ZeroAvia brought in-house when it acquired UK-based startup HyPoint in 2022. The company has just received UK government funding support to commercialize the HTPEM technology, which has higher power density than the low-temperature proton exchange membrane fuel cells used in its smaller ZA600 powertrain.

Miftakhov says ZeroAvia has now applied for certification of the 600-kW ZA600 with the FAA and UK Civil Aviation Authority aiming for market by the end of 2025. The first application is the Cessna Caravan, but the ZA600 is designed for retrofit to any nine-to-19-passenger aircraft powered by Pratt & Whitney Canada PT6-class turboprops. “We are building prototypes for certification testing,” he says.

The ZA2000 is planned to be flight tested on a De Havilland Dash 8-400 that is undergoing modification in Seattle. Initial testing of the powertrain has been completed using a ground rig. “We are progressing to higher-power testing, then integration [on the aircraft] and ground test. The earliest it could fly is a couple of years from now,” he said.