Robots will soon be making their commercial debut to remove aircraft paint and coatings. Dutch robotics specialist Xyrec is targeting the operational launch of its Laser Coating Removal (LCR) robotic system with a major aircraft manufacturer in mid-2023—and it has big plans for growth from there.

Xyrec moved into a custom-built facility at Port San Antonio in late 2020 and used the past two years to test and improve the LCR system. This included its successful demonstration of how the robot’s laser technology could be used to quickly and safely strip paint from aircraft such as the Boeing 727 and C-17. Xyrec CEO Peter Boeijink says that, using two robots, the system is capable of completely stripping paint from a C-17 in approximately 20 hr. He notes that traditional aircraft paint removal processes for this aircraft take approximately two weeks.

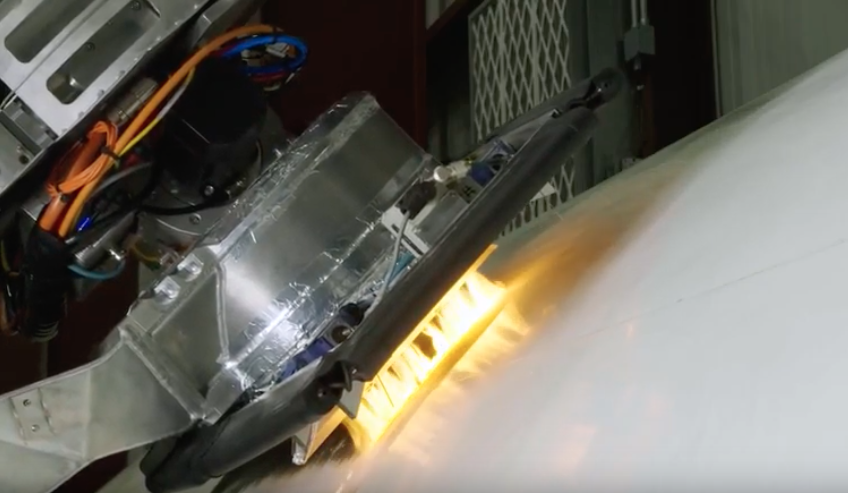

Credit: Xyrec

Boeijink says Xyrec is targeting a “robot-as-a-service” model, meaning customers will pay-per-job to remove paint with any color or substrate from any type of aircraft. Once the system is live at Xyrec’s launch customer, Boeijink plans to target implementation at the “big six” in the U.S., including American Airlines, Delta Air Lines, FedEx, Southwest, United and UPS. He notes that many airlines have moved toward outsourcing paint removal services due to the complexity and messy nature of this type of work.

Xyrec plans to establish six regional centers in the U.S. where these paint removal services will take place, two of which Boeijink expects to be open by the end of 2024. The company is also planning to target potential military customers, particularly since the U.S. Air Force has already invested significantly in the use of lasers to remove paint and coatings. He says the convenience and flexibility of offering the service close to these airlines’ maintenance facilities will provide a strong business case.

Also driving the business case, according to Boeijink, is increased pressure on aviation companies to control sustainability impacts within their supply chains. “The current model where operators are outsourcing [paint removal] is not using robots like we produce,” he notes, pointing out that it is “dirty, ugly work” that uses a large amount of chemicals and water. The LCR system vacuums paint particles as the laser passes over the aircraft surface, collecting them in a sack for disposal. Boeijink says the process results in only around 2 lb. of waste in powder form for a widebody aircraft, compared to approximately 475 gallons of chemicals and 3,700 gallons of water generated through traditional paint removal methods.

Besides its North American expansion plans, Boeijink says Xyrec hopes to establish 30 global sites by 2027. The facilities will offer both paint removal and robotic painting through its Automated Paint Robot, which Xyrec says offers quicker paint time, reduced paint usage and more consistent paint thickness.