The Mission Robotic Vehicle installs a Mission Extension Pod on a receiving satellite in this screen grab from a concept video.

Northrop Grumman’s SpaceLogistics subsidiary demonstrated a revolutionary way of extending the lives of satellites with the docking of its Mission Extension Vehicle to an Intelsat satellite in 2020. Now the company is looking toward the launch of products that not only would add longevity to existing spacecraft, but also be able to upgrade them on orbit.

SpaceLogistics has two Mission Extension Vehicles operating in space. Meanwhile, the company’s next generation of satellite servicing products is tracking toward a 2024 launch on a SpaceX rocket of a Mission Robotic Vehicle (MRV) carrying three Mission Extension Pods (MEP). SpaceLogistics is working in partnership with DARPA and the Naval Research Laboratory on the Robotic Servicing of Geosynchronous Satellites (RSGS) program.

- U.S. Space Force has created mobility and logistics office

- The vehicle and extension pods are designed to add capability to satellites

If the program is successful, the MRV and its MEPs may answer the call of commercial companies and government officials who want to keep assets on orbit longer, protect existing capabilities from attack or other damage and upgrade or change the capability of those satellites in space. Support within the government has been building for such in-space servicing activities. A year ago, the White House issued the In-Space Servicing, Assembly and Manufacturing National Strategy that has since seen an implementation plan put forward. And the U.S. Space Force has created a Space Access, Mobility and Logistics program to focus on refueling of satellites and space tugs and remediation of orbital debris.

Col. Meredith Beg, deputy director of operations, space mobility and logistics within Space Systems Command, said in February that the Space Force plans to establish a program of record to focus on mobility and logistics in space and will be exploring ways to use commercial capabilities to service geostationary satellites.

“What we need as a nation is a layered ability to protect [satellites, and] that means multiple orbits, different payloads disaggregated and put onto different systems,” says SpaceLogistics President Robert Hauge. “Everything we’re doing as a company today is about taking existing satellites and either life-extending them-—or we can also bring, with these pods, additional payloads. We can upgrade those satellites and give them more resiliency.”

That might include a space domain awareness sensor or countermeasures to add survivability to a legacy spacecraft, he says. The MEPs are designed to last six years. The U.S. has numerous high-value spacecraft in geosynchronous orbit, including the Advanced Extremely High-Frequency satellite systems, to provide secure strategic communications to the Air Force and secure tactical communications to the battlefield, Geosynchronous Space Situational Awareness spy satellites, the Space-Based Infrared System missile warning constellation and Wideband Global Satcom that provide Ka- and X-band communications.

“We absolutely should build the new systems. But my concern is, as the threats are rising in space, our adversaries may not give us the time to field all those new systems,” Hauge says. “The issue isn’t, ‘Do I build a new, more resilient system? Or do I extend and enhance the legacy system?’ It’s an add-on, because for a fraction of the cost of a new system, you can also have the ability to extend and enhance these legacy systems.”

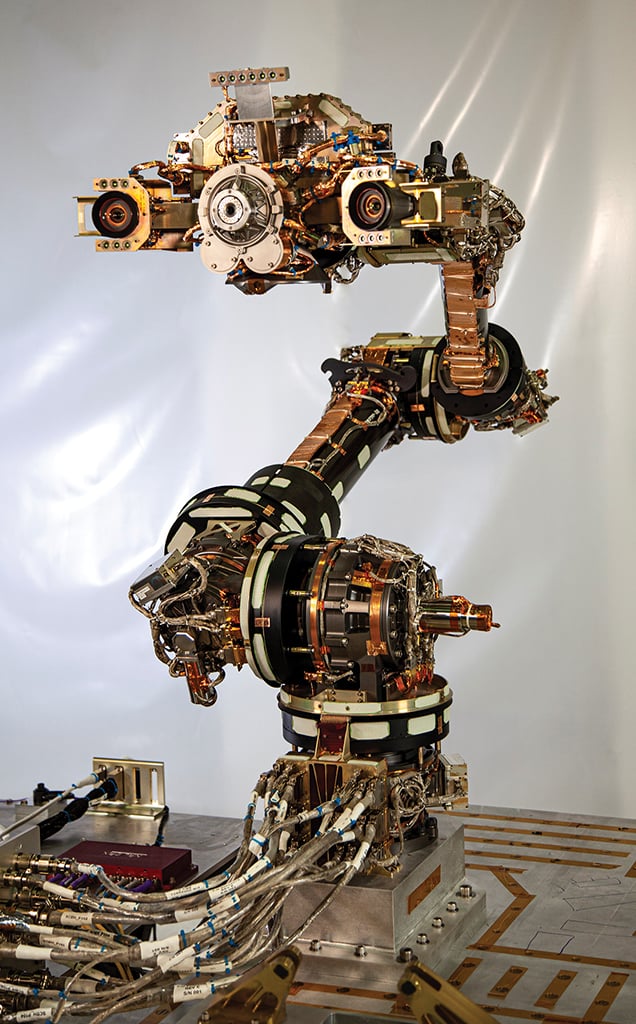

Northrop’s MRV, a spacecraft the size of a van that has two robotic arms, carries three dishwasher-size MEPs into space. The MEPs separate, and all four spacecraft use solar-electric propulsion to make their way to geosynchronous orbit. The MEPS position themselves close to the satellites they are to assist. The MRV then approaches each MEP in turn. The MRV’s robotic arm captures the MEP, grasps the satellite, maneuvers it to be close to the receiving satellite and docks the MEP. The MRV then backs away and observes to ensure successful docking before installing the next pod.

Northrop completed a critical design review on the platform last fall. Seven of nine avionics boxes required to operate the vehicle’s two robotic arms are in place in Dulles, Virginia.

All of the components have been delivered to integration and testing, and all but the second arm are ready to be installed onto the spacecraft structure, says Ana Saplan, DARPA’s RSGS program manager. The avionics the Naval Research Laboratory developed for the RSGS program are finished. Two of the components that have been tested and integrated are still being used at the Naval Research Laboratory to ensure the second arm completes testing. Northrop Grumman has begun integration with the Naval Research Laboratory for internal components. The structure then will be shipped to the laboratory, where the external components will be installed. “It’s kind of a back-and-forth but very coordinated because both teams are in both locations during the testing and the integration,” Saplan says. Flight qualification testing is expected to finish in April.

Northrop integrates the MEPs in Gilbert, Arizona, at its small-satellite factory and is trying to produce MEPs in quantities that would make them affordable—“several” per year. The company is working on its commercial model and has a contract with Australian satellite operator Optus for one MEP. It is close to finalizing contracts for the next two MEPs, too, and has received deposits for them. “That’s going to be really important for us because once those first three are secured, that means our first launch is closed,” Hauge says. “We’re in discussions with a number of different companies for follow-on mission extension pods.”

The government is likely to be another source of income for the program. Congress provided a plus-up of $30 million for the Space Force’s in-space servicing efforts in fiscal 2023, and future programming is expected to begin in 2025. Until then, funding for in-space servicing may come from a variety of budget lines within research and development, as well as operations and maintenance accounts.

DARPA plans to demonstrate a set of four missions. Using the dexterous robotic arms for close inspection, anomaly correction, relocation and upgrades are missions consistent with what SpaceLogistics has planned. But DARPA also aims to demonstrate a similar capability with a spacecraft that is smaller than the MEP, Saplan says. That would not be a simple task, as it would involve developing specific algorithms and features. “We just know we can do it—if somebody wants to do it. For instance, if the government wants to send up a small payload, they can.”

The MRV and MEP technologies, much like robotic arms, could conceivably be used for offensive military purposes in addition to more benign life-extension missions. To address that, officials at SpaceLogistics have taken care to participate in international standards organizations that make recommendations on principles and practices for rendezvous and proximity operations, an attempt to be responsible, cooperative and transparent—as is critical for building an industry.

Joe Anderson, vice president of operations and business development for SpaceLogistics, is also a board member of the Consortium for the Execution of Rendezvous and Servicing Operations, a not-for-profit trade association established to recommend technical standards and policies for satellite servicing. He has seen the organization grow in less than a decade from a handful of founding members to more than 60.

Saplan has seen momentum build for satellite servicing as well. “The capabilities that RSGS enables have caught the attention of a larger community than when we first started RSGS, and the naysayers said this [was] never going to happen,” she says. “In that time, Northrop Grumman has shown [its Mission Extension Vehicle and] other countries have shown their capabilities. People are really looking at RSGS as something that is going to happen and going to change the landscape of space.”

Editor's note: This article has been updated to clarify information about development of the avionics for RSGS program.