NLR Developing Robotic Mechanic to Alleviate MRO Workforce Demand

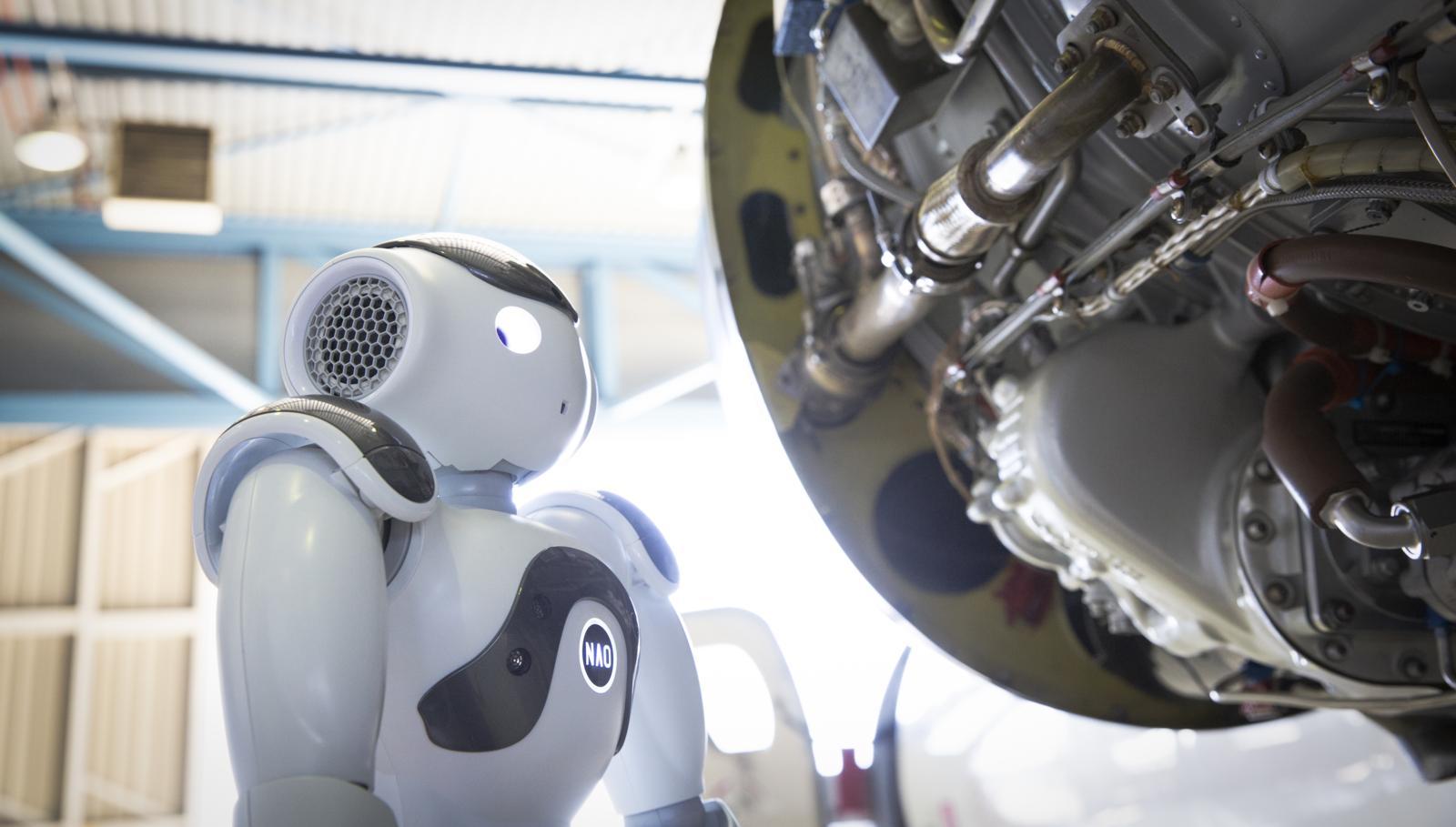

The Netherlands Aerospace Laboratory (NLR) is developing a robotic mechanic to alleviate the increased need for maintenance technicians it anticipates in the industry post-pandemic. Named ARVI (autonomous robot for visual inspections), NLR says the robot is “an apprentice mechanic” that can navigate through a hangar and perform aircraft inspections just like human technicians.

“What we have envisioned is that in the future it will be more difficult to get technicians working on aircraft,” says Arjan De Jong, principal at NLR. “We expect a rise in the number of aircraft in the future, despite the COVID situation. We expect technicians to leave the industry as a result of COVID, so we are looking for ways to improve productivity—and one of the solutions might be to use robots to carry out work that technicians normally do.”

The first task NLR is programming ARVI for is to carry out visual inspections to map and detect defects such as dents, scratches, broken wires, corrosion, dirt or leakages. Its team has been testing out pairing a robotic vehicle that can move around an aircraft with various types of sensors and cameras, such as traditional color cameras as well as thermal or spectral imaging.

De Jong says NLR has developed means to interpret and analyze the images taken by the robot to distinguish various types of damage. Using a combination of software purchased off the shelf and maintenance-specific software tools it is developing in-house, NLR is using neural based analysis and artificial intelligence to perform analysis. Software to automate the robots’ movements is based on PC technology, so De Jong says NLR is “very flexible” with programming its robots.

Some examples of automation that it is testing and developing are a device to scan the leading edge of an aircraft and a robot that uses thermal imaging to inspect both the inside and outside of helicopter rotor blades.

“Where we want to end is an infinite number of sensors that will be able to do the work, that are small enough to be carried around or through aircraft, and that can actually attach to a robot that can move through the aircraft and do all the inspections that are normally done by technicians,” he says.

NLR began development of ARVI approximately three years ago on an experimental basis and is now working with the Dutch Ministry of Defense to test the technology. De Jong says NLR is looking to expand ARVI’s scope and find other aviation companies that are willing to cooperate on its development.

According to De Jong, he expects NLR’s rotor blade scanner to be finished by early 2021 and then it will need at least a year to make the technology more affordable and work towards miniaturized sensors. Once this is complete, he estimates that NLR will have a minimum viable product for the market in a year or two.