Credit: Jamco

From a passenger’s point of view, the aircraft cabin feels very different in 2021 than it did prior to the onset of the COVID-19 pandemic. Fears about spread of the virus have driven some airlines to implement social distancing guidelines and install new features aimed at sanitizing elements of the cabin. Innovative new design concepts to transform galleys into passenger social zones or self-service areas seem unrealistic now when they appeared to be the wave of the future going into 2020.

“There was a large push to create products that have the ability to transform galleys from a working area to a social area, or to simply improve the looks of the galley,” says Brian Schmalz, vice president sales and marketing, galley inserts, Collins Aerospace. Although social distancing guidelines have stunted some of the excitement over these types of innovations, he says, airlines are beginning to realize that some of these galley innovations actually provide opportunity to limit direct contact between passengers and crew, as well as to allow greater distancing between staff.

From a passenger’s point of view, the aircraft cabin feels very different in 2021 than it did prior to the onset of the COVID-19 pandemic. Fears about spread of the virus have driven some airlines to implement social distancing guidelines and install new features aimed at sanitizing elements of the cabin. Innovative new design concepts to transform galleys into passenger social zones or self-service areas seem unrealistic now when they appeared to be the wave of the future going into 2020.

“There was a large push to create products that have the ability to transform galleys from a working area to a social area, or to simply improve the looks of the galley,” says Brian Schmalz, vice president sales and marketing, galley inserts, Collins Aerospace. Although social distancing guidelines have stunted some of the excitement over these types of innovations, he says, airlines are beginning to realize that some of these galley innovations actually provide opportunity to limit direct contact between passengers and crew, as well as to allow greater distancing between staff.

Credit: AIM Altitude

“Before the pandemic, galleys were starting to change aesthetically. Galley areas were still functional spaces, but the galleys themselves were receiving little touches to pull them into the wider design themes,” notes Ross Burns, head of industrial design at AIM Altitude and AVIC Cabin Systems. Post-COVID, he says, the future of galley development will be much more heavily focused on automation such as touchless features and air purification.

“Before the pandemic, galleys were starting to change aesthetically. Galley areas were still functional spaces, but the galleys themselves were receiving little touches to pull them into the wider design themes,” notes Ross Burns, head of industrial design at AIM Altitude and AVIC Cabin Systems. Post-COVID, he says, the future of galley development will be much more heavily focused on automation such as touchless features and air purification.

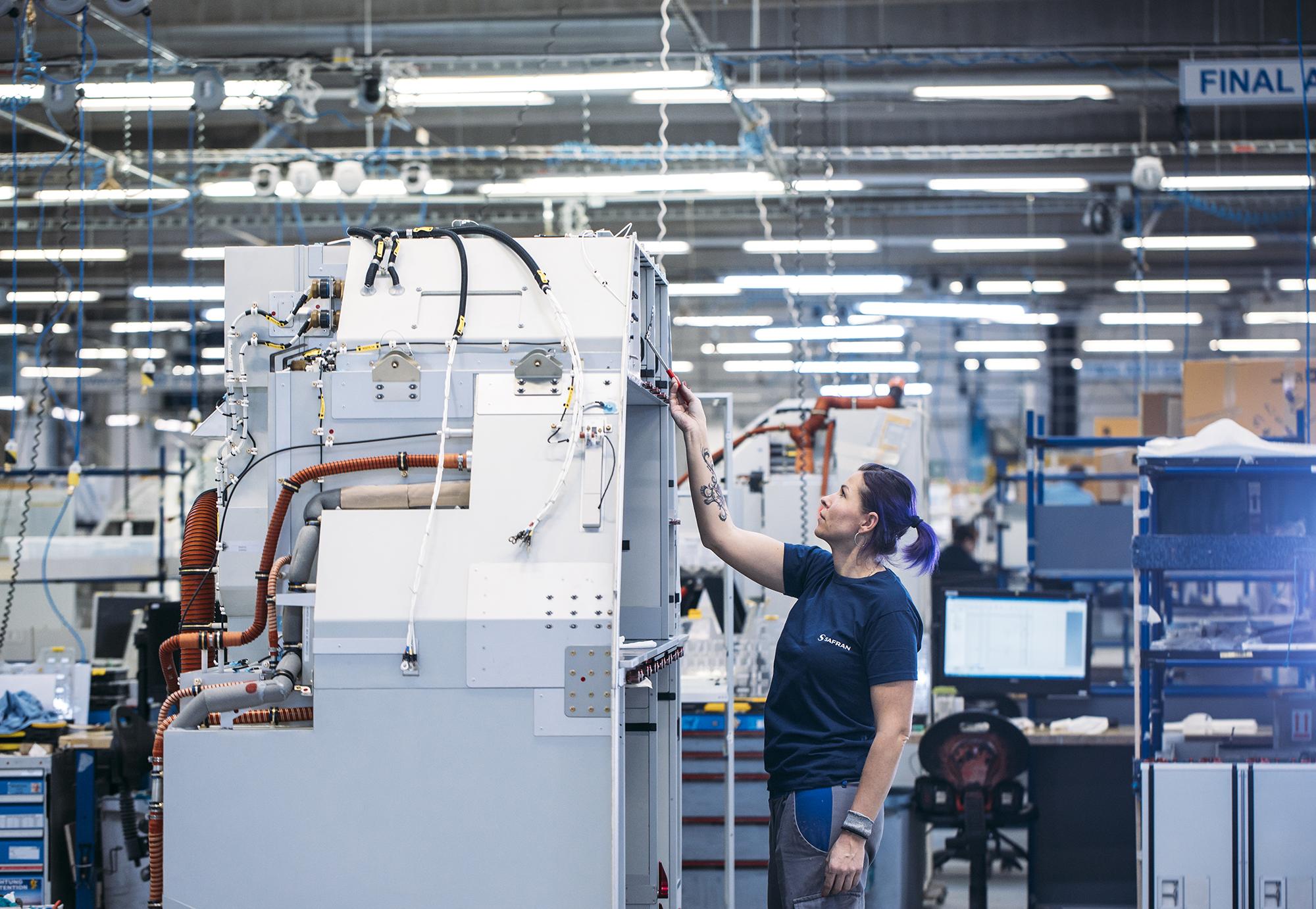

Credit: Safran Cabin

According to Julie Imbert, marketing director at Safran Cabin, connectivity and touchless applications were trending in galley developments pre-pandemic. “I believe that following the pandemic, those trends will still be valid, but considered from a different angle and a different rhythm by operators,” she says. “For instance, touchless applications are now also considered to support hygiene improvements. Sustainability is gaining visibility in some regions, especially in Europe, and of course hygiene has quite the spotlight. In the galley environment, sustainability doesn’t only imply making our products more sustainable, but also to work on developing solutions to help our customers improve their own practices.” In these areas, she says, Safran Cabin believes digitalization will play a big role.

According to Julie Imbert, marketing director at Safran Cabin, connectivity and touchless applications were trending in galley developments pre-pandemic. “I believe that following the pandemic, those trends will still be valid, but considered from a different angle and a different rhythm by operators,” she says. “For instance, touchless applications are now also considered to support hygiene improvements. Sustainability is gaining visibility in some regions, especially in Europe, and of course hygiene has quite the spotlight. In the galley environment, sustainability doesn’t only imply making our products more sustainable, but also to work on developing solutions to help our customers improve their own practices.” In these areas, she says, Safran Cabin believes digitalization will play a big role.

Credit: Diehl Aviation

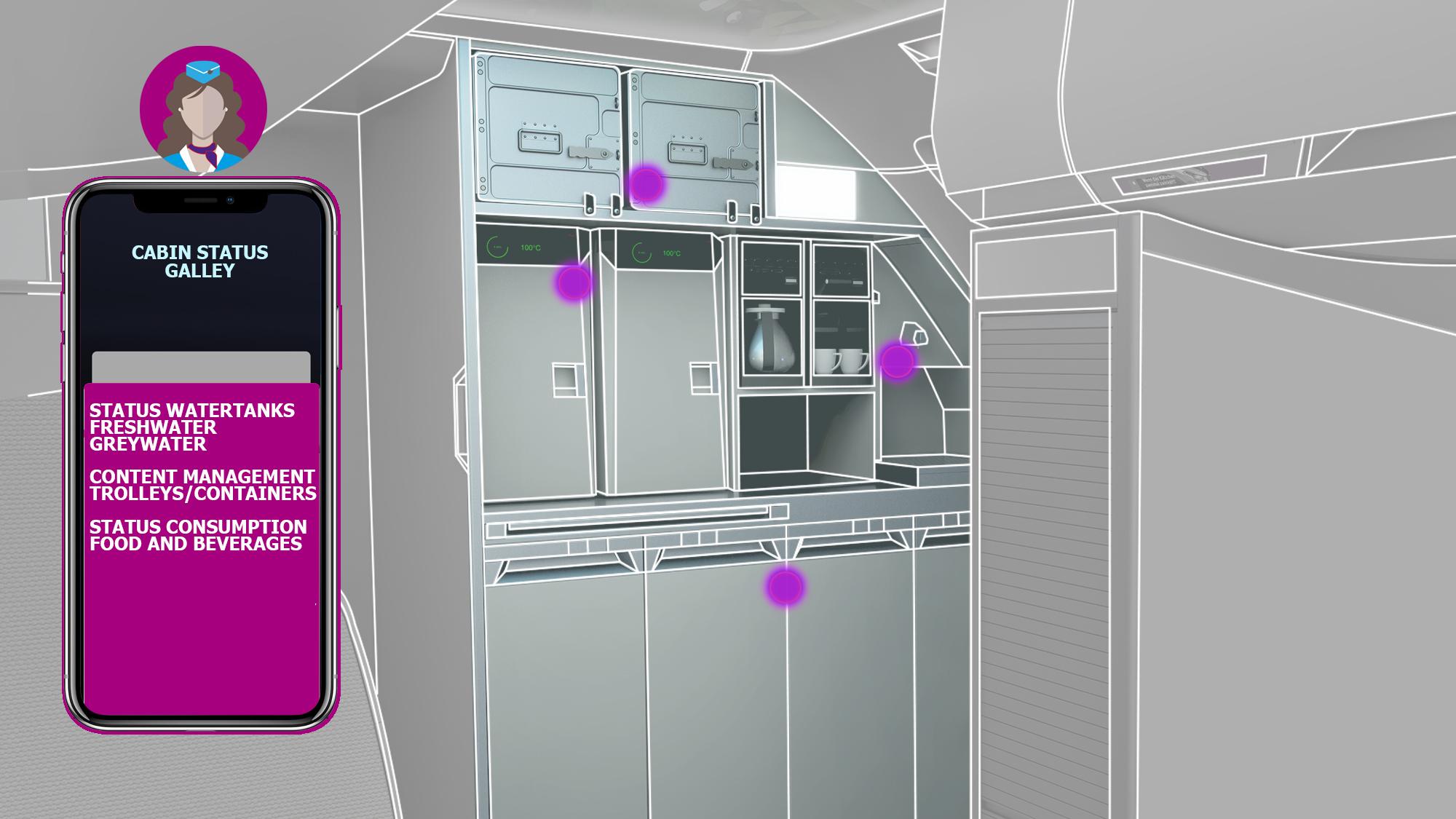

As aircraft become more digital and the connected cabin ecosystem evolves, interiors specialists are eyeing galleys as an area ripe for innovation. Diehl Aviation is working on smart galley concepts that incorporate technology such as Big Data and radio frequency identification (RFID) to improve cabin crew operations and galley maintenance. Its eSmartGalley concept would enable airlines to collect, process and transmit data for predictive health management and Diehl says remote maintenance functions could enable specialists on the ground to solve galley issues with minimal impact on cabin crew operations. The system would be further digitalized through a touch screen interface, digital inventory management and RFID-trolley detection.

As aircraft become more digital and the connected cabin ecosystem evolves, interiors specialists are eyeing galleys as an area ripe for innovation. Diehl Aviation is working on smart galley concepts that incorporate technology such as Big Data and radio frequency identification (RFID) to improve cabin crew operations and galley maintenance. Its eSmartGalley concept would enable airlines to collect, process and transmit data for predictive health management and Diehl says remote maintenance functions could enable specialists on the ground to solve galley issues with minimal impact on cabin crew operations. The system would be further digitalized through a touch screen interface, digital inventory management and RFID-trolley detection.

Credit: Safran Cabin

Safran Cabin has been developing a number of digitalized Smart Galley solutions that tie in with the concept of a connected cabin. These include smart sensors to monitor the galley systems and an Integrated e-Panel able to support current and future connectivity applications within the cabin environment. It says the Integrated e-Panel will work like a digital hub, facilitating the integration of new features within the galley and cabin environment.

Safran Cabin has been developing a number of digitalized Smart Galley solutions that tie in with the concept of a connected cabin. These include smart sensors to monitor the galley systems and an Integrated e-Panel able to support current and future connectivity applications within the cabin environment. It says the Integrated e-Panel will work like a digital hub, facilitating the integration of new features within the galley and cabin environment.

Credit: Safran Cabin

Safran Cabin’s smart galley developments also include SOPHY, a smart trolley solution that collects, shares and communicates real-time data related to movement, impact, temperature, pressure, status and more with other equipment through what it calls a “mesh network” to control and optimize catering operations. According to Imbert, “SOPHY is truly unique as it is offering much more than a traditional tracking solution.” She notes that it has been designed for easy, seamless integration in any trolley and container from any airline. “We have designed SOPHY in a way that will allow easy upgrades of the solution with more features in the future, and more and more integration with the rest of the cabin environment as new offers and opportunities are developed,” she says.

Safran Cabin’s smart galley developments also include SOPHY, a smart trolley solution that collects, shares and communicates real-time data related to movement, impact, temperature, pressure, status and more with other equipment through what it calls a “mesh network” to control and optimize catering operations. According to Imbert, “SOPHY is truly unique as it is offering much more than a traditional tracking solution.” She notes that it has been designed for easy, seamless integration in any trolley and container from any airline. “We have designed SOPHY in a way that will allow easy upgrades of the solution with more features in the future, and more and more integration with the rest of the cabin environment as new offers and opportunities are developed,” she says.

Credit: Safran Cabin

Safran Cabin also offers a variety of galley insert products, such as its new Peltier compartment, which is a fully customizable cooling or warming compartment that Imbert says is lower weight and quieter than standard chillers.

Safran Cabin also offers a variety of galley insert products, such as its new Peltier compartment, which is a fully customizable cooling or warming compartment that Imbert says is lower weight and quieter than standard chillers.

Credit: Safran Cabin

According to Imbert, Safran Cabin has concentrated efforts on maintainability of moving parts and work areas where food is being prepared. “Imagine if your dinner table was used to prep 250 meals every single day, and you can imagine how intense the wear and tear is on work surfaces,” she says. “So we are always looking at new materials and balancing the need for low weight with high durability.” In light of the pandemic, it is also working on a range of solutions to support operators in sanitization of materials and surfaces through a newly-launched partnership with 3M.

According to Imbert, Safran Cabin has concentrated efforts on maintainability of moving parts and work areas where food is being prepared. “Imagine if your dinner table was used to prep 250 meals every single day, and you can imagine how intense the wear and tear is on work surfaces,” she says. “So we are always looking at new materials and balancing the need for low weight with high durability.” In light of the pandemic, it is also working on a range of solutions to support operators in sanitization of materials and surfaces through a newly-launched partnership with 3M.

Credit: AIM Altitude

AIM Altitude is preparing to introduce a new galley system at Aircraft Interiors Expo 2021 that it says will have benefits for both sustainability goals and efforts to mitigate the spread of COVID-19. Instead of following the traditional tray and cart system, ARCA uses a boxed meal concept which eliminates trays in favor of stackable meal packs. The boxed meals, which can be customized by passengers while booking flights, are then delivered using lightweight folding carts that AIM Altitude says results in space savings equivalent to an extra row of seating.

AIM Altitude is preparing to introduce a new galley system at Aircraft Interiors Expo 2021 that it says will have benefits for both sustainability goals and efforts to mitigate the spread of COVID-19. Instead of following the traditional tray and cart system, ARCA uses a boxed meal concept which eliminates trays in favor of stackable meal packs. The boxed meals, which can be customized by passengers while booking flights, are then delivered using lightweight folding carts that AIM Altitude says results in space savings equivalent to an extra row of seating.

Credit: AIM Altitude

“The ARCA system was developed prior to the COVID-19 pandemic, but many of the elements are particularly helpful in minimizing contact and maintaining hygiene,” says Burns. “Crew members no longer have to handle open meal trays or any loose components. With fewer components for the meal services, there are fewer fiddly items to cleanse,” says Burns.

He adds that the lower weight of the system results in reduced fuel burn and maintenance requirements, while the overall design reduces volume of waste. After meal service, the boxes become containers for waste collection, which Burns says enables separating the elements into different recyclables. “Back at the galley, many of the containers are compressed by a waste compactor that reduces the volume of the waste. The remainder are stored back within the refrigerated aisle stowage walls, separating recycling for efficient stowage during the remainder of the flight,” he says. “At the destination, caterers can easily identify and remove the different types of waste and recycling.”

“The ARCA system was developed prior to the COVID-19 pandemic, but many of the elements are particularly helpful in minimizing contact and maintaining hygiene,” says Burns. “Crew members no longer have to handle open meal trays or any loose components. With fewer components for the meal services, there are fewer fiddly items to cleanse,” says Burns.

He adds that the lower weight of the system results in reduced fuel burn and maintenance requirements, while the overall design reduces volume of waste. After meal service, the boxes become containers for waste collection, which Burns says enables separating the elements into different recyclables. “Back at the galley, many of the containers are compressed by a waste compactor that reduces the volume of the waste. The remainder are stored back within the refrigerated aisle stowage walls, separating recycling for efficient stowage during the remainder of the flight,” he says. “At the destination, caterers can easily identify and remove the different types of waste and recycling.”

Credit: AIM Altitude

AIM Altitude believes ARCA could gain significant traction as the aviation industry adapts post-pandemic. “ARCA was produced as a creative-thinking design exercise, but it has become apparent how this trend has become more and more relevant,” says Burns, noting that AIM Altitude has been developing a single-aisle version during the COVID-19 period. “We see the single-aisle aircraft, especially the long-range fleets, such as the A321XLR and B737 MAX, as a very exciting new platform. This is where we see how ARCA’s space-efficient properties could really offer huge benefits to new LOPA layouts, in terms of delivering two meal services, like a typical long-haul offering, within a smaller footprint,” he says.

AIM Altitude believes ARCA could gain significant traction as the aviation industry adapts post-pandemic. “ARCA was produced as a creative-thinking design exercise, but it has become apparent how this trend has become more and more relevant,” says Burns, noting that AIM Altitude has been developing a single-aisle version during the COVID-19 period. “We see the single-aisle aircraft, especially the long-range fleets, such as the A321XLR and B737 MAX, as a very exciting new platform. This is where we see how ARCA’s space-efficient properties could really offer huge benefits to new LOPA layouts, in terms of delivering two meal services, like a typical long-haul offering, within a smaller footprint,” he says.

Credit: AIM Altitude

While ultra-long-haul flights have been greatly reduced during the pandemic, AIM Altitude introduced another concept for galley flexibility that was shortlisted for the 2019 Crystal Cabin Awards. The Ultraflex design features a transformable space that can be adapted throughout the flight for different passenger requirements, such as a wellness, prayer or private dining space. The concept includes a Deli Galley, which is an extended-height refrigerated food cabinet where passengers can help themselves to snacks and drinks.

While ultra-long-haul flights have been greatly reduced during the pandemic, AIM Altitude introduced another concept for galley flexibility that was shortlisted for the 2019 Crystal Cabin Awards. The Ultraflex design features a transformable space that can be adapted throughout the flight for different passenger requirements, such as a wellness, prayer or private dining space. The concept includes a Deli Galley, which is an extended-height refrigerated food cabinet where passengers can help themselves to snacks and drinks.

Credit: AIM Altitude

AIM Altitude has also introduced a number of galley features designed for easier operation and maintenance. These include clip-on trim, replaceable décor panels, a folding ergonomic footstep, a customizable pull-out pantry, and a pull-out table that sits flush with the galley worktop to simplify meal preparation, cleaning and sanitization.

AIM Altitude has also introduced a number of galley features designed for easier operation and maintenance. These include clip-on trim, replaceable décor panels, a folding ergonomic footstep, a customizable pull-out pantry, and a pull-out table that sits flush with the galley worktop to simplify meal preparation, cleaning and sanitization.

Credit: Collins Aerospace

Like AIM Altitude, Collins Aerospace recently launched a product aimed at galley flexibility. Its M-Flex Duet product, a 2019 Crystal Cabin Awards finalist, transforms the aircraft doorway into either a self-serve social zone or cabin attendant working area. During flights, the compact monuments can be unfolded to provided extended galley space. Since the product has been designed to fit within standard monument footprints, Collins says it can be easily installed as a line-fit or retrofit solution.

Like AIM Altitude, Collins Aerospace recently launched a product aimed at galley flexibility. Its M-Flex Duet product, a 2019 Crystal Cabin Awards finalist, transforms the aircraft doorway into either a self-serve social zone or cabin attendant working area. During flights, the compact monuments can be unfolded to provided extended galley space. Since the product has been designed to fit within standard monument footprints, Collins says it can be easily installed as a line-fit or retrofit solution.

Credit: Collins Aerospace

“Airlines have been looking for ways to integrate more passenger self-service amenities in recent years,” says Jefferey McKee, director of customer experience and design, Collins Aerospace. “M-Flex Duet provides a flexible premium service area, offering passengers the ability to move about the cabin to grab a beverage or snack, without impacting revenue-generating seat count for airlines.” McKee notes that the product also expands catering options and can adapt to airlines’ pandemic-related shifts toward minimizing crew and passenger contact through adjusted service models.

“Airlines have been looking for ways to integrate more passenger self-service amenities in recent years,” says Jefferey McKee, director of customer experience and design, Collins Aerospace. “M-Flex Duet provides a flexible premium service area, offering passengers the ability to move about the cabin to grab a beverage or snack, without impacting revenue-generating seat count for airlines.” McKee notes that the product also expands catering options and can adapt to airlines’ pandemic-related shifts toward minimizing crew and passenger contact through adjusted service models.

Credit: Collins Aerospace/Knight Aerospace

Although galley designs are usually focused on commercial aircraft, Collins Aerospace recently partnered with Knight Aerospace, a provider of modular and palletized systems for aircraft, on an innovative new galley product for military cargo aircraft. The Air Transportable Galley/Lavatory System (ATGL) is a universal system featuring a full-service galley and two lavatories mounted on a customized pallet that can be loaded on board any cargo aircraft. The ATGL interfaces with the aircraft cargo handling system and can be rolled on and off an aircraft in less than 30 mins. Customers can choose between a variety of options for the galley, including different combinations of refrigerators, coffee makers, ovens and microwaves. According to the companies, the ATGL is targeted toward use cases serving military personnel during long missions in which aircraft either lack or feature insufficient galley and lavatory functionality.

Although galley designs are usually focused on commercial aircraft, Collins Aerospace recently partnered with Knight Aerospace, a provider of modular and palletized systems for aircraft, on an innovative new galley product for military cargo aircraft. The Air Transportable Galley/Lavatory System (ATGL) is a universal system featuring a full-service galley and two lavatories mounted on a customized pallet that can be loaded on board any cargo aircraft. The ATGL interfaces with the aircraft cargo handling system and can be rolled on and off an aircraft in less than 30 mins. Customers can choose between a variety of options for the galley, including different combinations of refrigerators, coffee makers, ovens and microwaves. According to the companies, the ATGL is targeted toward use cases serving military personnel during long missions in which aircraft either lack or feature insufficient galley and lavatory functionality.

Credit: Collins Aerospace

Another new galley product set to enter service soon is Collins’ Essence Premier oven, part of the Essence inserts collection. The insert includes a titanium inner oven to reduce weight and improve temperature efficiency. It also has what Collins calls a “revolutionary adaptive intelligent cooking feature,” which independently monitors cooking progress and can automatically make changes as needed without manual checks by flight attendants.

Schmalz says all of Collins’ galley cooking equipment has been engineered as line-replaceable-units (LRU) for easier maintainability. “We are continuing to explore ways to further reduce replacement time of products that have traditionally had more challenging access, such as galley air chillers,” he says. Schmalz adds that the next big maintenance innovations for the LRUs will likely pertain to real-time equipment monitoring, predictive maintenance and connectivity.

Another new galley product set to enter service soon is Collins’ Essence Premier oven, part of the Essence inserts collection. The insert includes a titanium inner oven to reduce weight and improve temperature efficiency. It also has what Collins calls a “revolutionary adaptive intelligent cooking feature,” which independently monitors cooking progress and can automatically make changes as needed without manual checks by flight attendants.

Schmalz says all of Collins’ galley cooking equipment has been engineered as line-replaceable-units (LRU) for easier maintainability. “We are continuing to explore ways to further reduce replacement time of products that have traditionally had more challenging access, such as galley air chillers,” he says. Schmalz adds that the next big maintenance innovations for the LRUs will likely pertain to real-time equipment monitoring, predictive maintenance and connectivity.

Credit: Collins Aerospace

On the sustainability side, Collins has been investing in thermoplastic composite materials and additive design manufacturing to create galley products that are stronger, higher quality and lighter weight, which Schmalz says will help reduce total cost of ownership by lowering fuel burn and cutting greenhouse gas emissions. “And that’s not even to mention the time, material, chemical and energy reduction in manufacturing and allowing for significant improvements in recyclability of materials,” he adds.

On the sustainability side, Collins has been investing in thermoplastic composite materials and additive design manufacturing to create galley products that are stronger, higher quality and lighter weight, which Schmalz says will help reduce total cost of ownership by lowering fuel burn and cutting greenhouse gas emissions. “And that’s not even to mention the time, material, chemical and energy reduction in manufacturing and allowing for significant improvements in recyclability of materials,” he adds.

Galleys are getting cleaner, greener and more connected as the aviation industry rethinks cabin designs in the wake of the pandemic.