EarthBay

EarthBay seeks to transform aircraft cargo doors into sets of windows to open up possibilities for premium cabin space in the lower deck. The product, which would be interchangeable with cargo doors on widebody aircraft, replaces the door with a metallic framing structure and large window sets—so it could be embedded on in-service or new aircraft. EarthBay says passengers could access the premium lower deck space by stairs once the aircraft is in cruise conditions, and the concept could provide additional revenue streams for airlines.

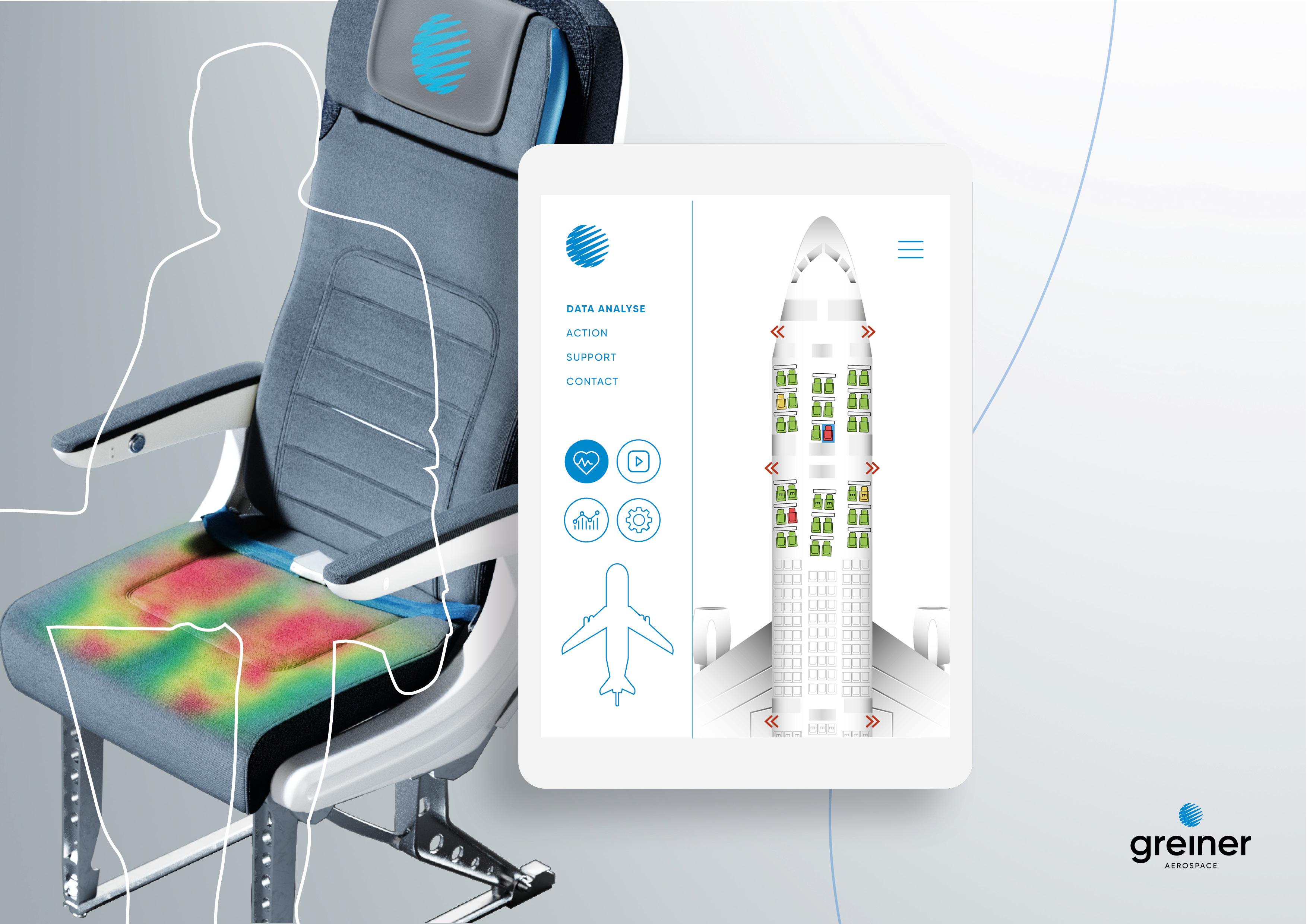

Intelligent Seat

Credit: Greiner

Greiner’s Intelligent Seat features an aircraft seat cushion with integrated sensor electronics, which can be used for both predictive maintenance and monitoring of passenger well-being. Data from the sensors is stored, evaluated and displayed through a digital IoT platform, which airlines can collect and query continuously to monitor the condition of the aircraft seats. A status report can be forwarded to ground staff before landing so maintenance staff are notified in advance about seat cushions that need replacement or seats that have been soiled. Meanwhile, flight attendants can monitor the status of seat temperature in-flight to draw conclusions about a passenger’s well-being.

Boeing Premium Flooring

Credit: Boeing

Designed to emulate high end flooring solutions with better longevity and maintainability, Boeing’s premium flooring product is a durable system made of pre-fabricated panels. Boeing says the panels feature a revolutionary attachment method that decouples the flooring from the structure beneath, which enables operators to replace a single panel that is scuffed or damaged rather than needing to replace entire sections. According to Boeing, the product can resolve recurring galley mat issues such as buckling, blistering and telegraphing.

i+sCabin

Credit: Diehl Aerospace

As a collaboration between project lead Diehl Aerospace and a consortium of aviation companies and universities, the i+sCabin is an intelligent concept that aims to connect separate cabin applications without cabling to one another. The solution would connect cabin elements such as seating, galleys, lavatories, sensors and cabin surfaces to create an “intelligent cabin network,” which would provide a real-time overview of the status of all aircraft cabin areas. According to Diehl, this would be particularly valuable in predicting potential faults for maintenance purposes.

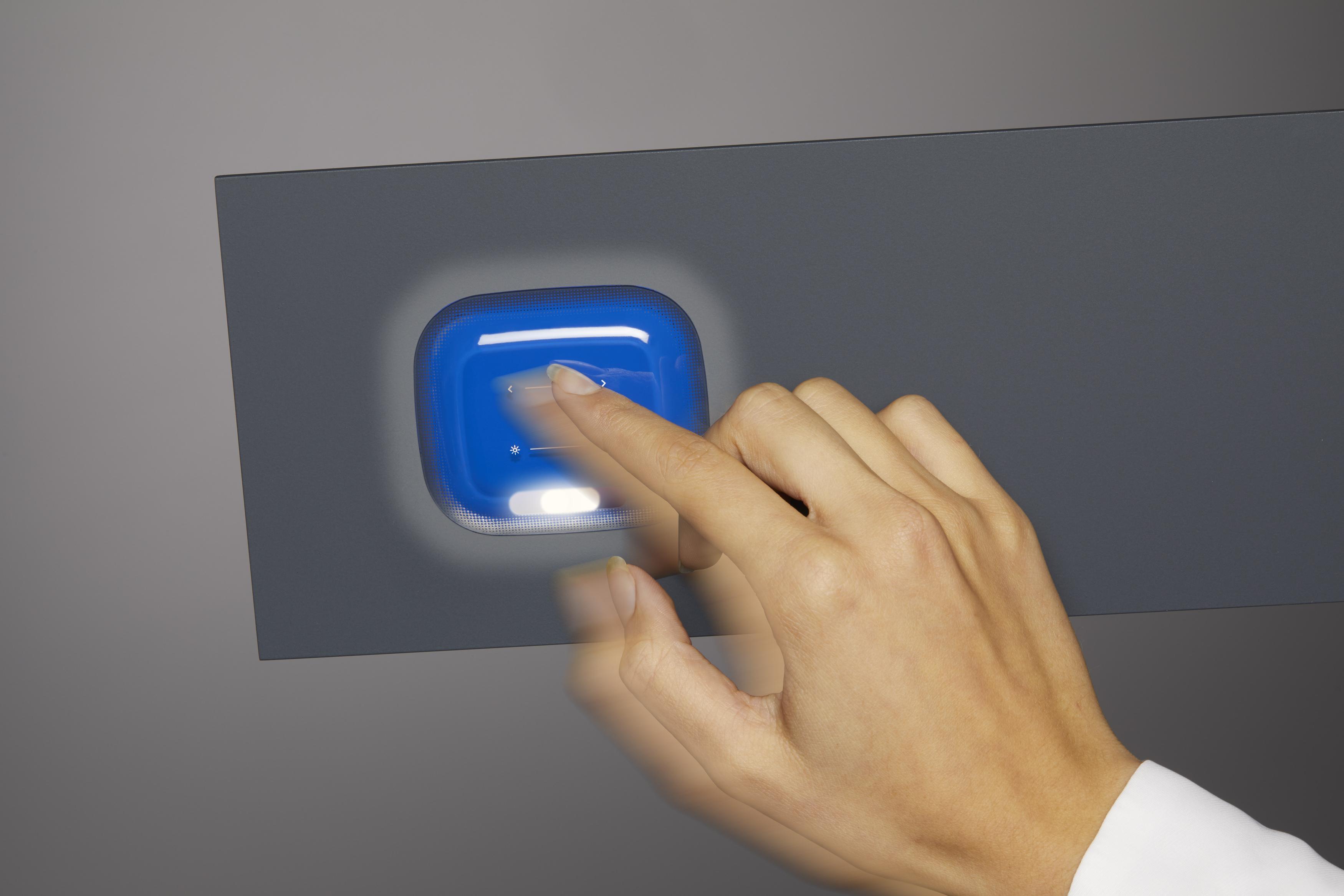

Jade Reading Light

Credit: Schott

Schott’s Jade product brings a touch screen experience to the operation of reading lights. Passengers adjust position and brightness of the lights through swiping and the lights can be printed with any design for airline customization. According to Schott, Jade’s monolithic glass cover is easy to clean and reduces the need for maintenance and repairs by up to 90%.

Chaise Longue

Credit: Delft University

This wild-looking seating concept from Delft University seeks to enable better comfort and healthy posture for passengers through more freedom to move around into different positions for sleeping, reading and eating. To optimize available space in the aircraft, some seats are hung from the ceiling so two rows of seats can take up the same floor space.

RAVE Bluetooth Audio

Credit: Safran

Safran Passenger Innovations has “cracked the code” to enable an entire aircraft to be connected to Bluetooth audio at the same time, which it says will solve Bluetooth audio congestion during flights. According to the company, commercially available Bluetooth prevents a large number of Bluetooth headphones to operate in close proximity without impacting Wi-Fi. Safran’s RAVE Bluetooth Audio solution, which works through an antenna found in Safran displays and custom software, controls the power, antenna direction and protocol to enable each passenger to connect to Bluetooth audio without impacting connection for other seats.

Seat Heating and Cooling System

Credit: Lantal

Lantal is looking to bring the seat heating and cooling technology currently available in cars to aircraft seats. The company’s Seat Heating and Cooling System uses Gentherm technology, consisting of a smart controller, heater mat, heat conductor and air moving device to create “individually adjusted microclimates” for first- and business-class passengers. The seats also feature special seat cover fabrics to enable optimum airflow and continuous moisture extraction to ensure dry seat surfaces. According to Lantal, the modular system is easy to install and meets all airworthiness requirements.

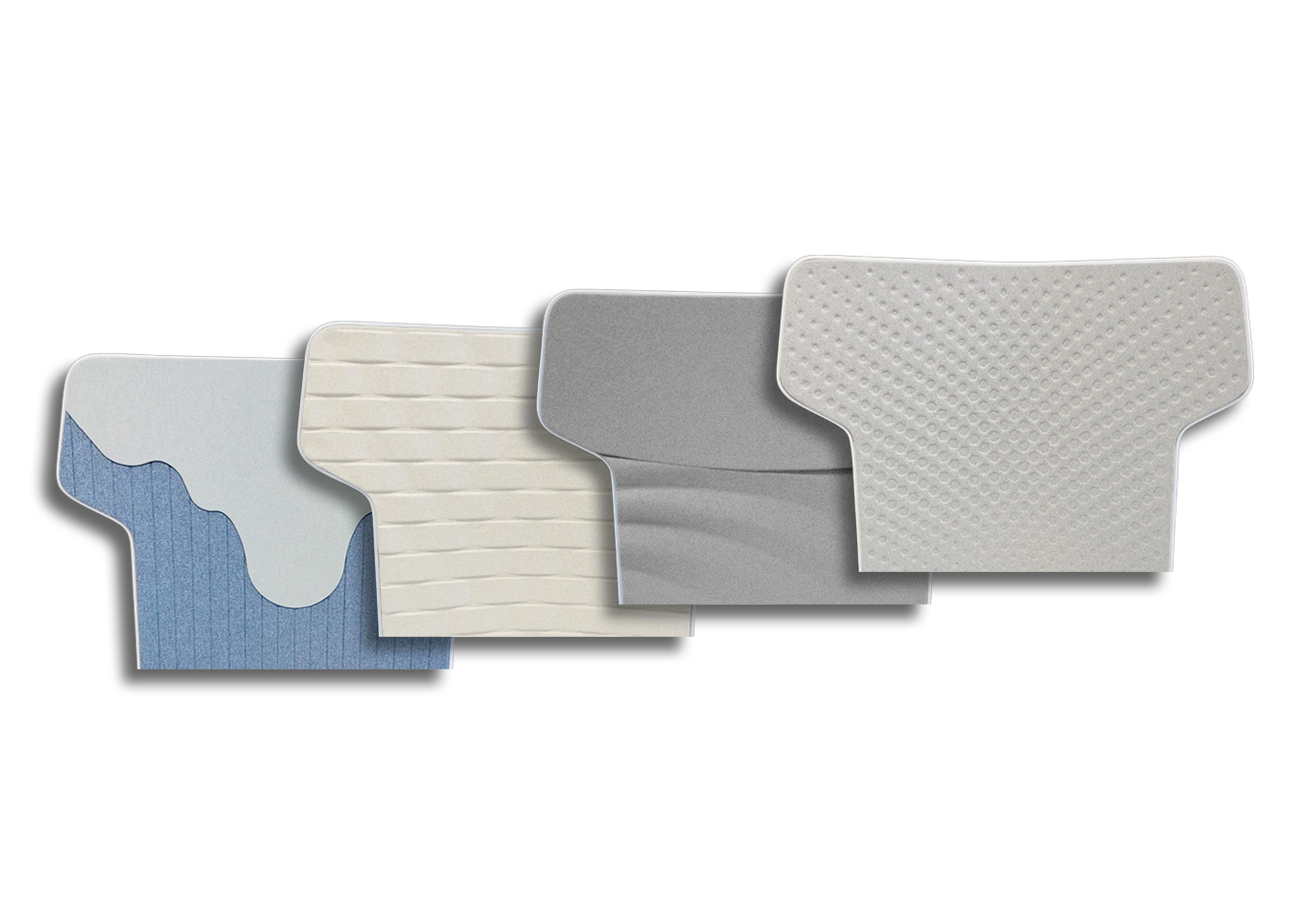

MGRSoftWall NextGen

Credit: MGR Foamtex

Developed by MGR Foamtex and Zotefoams, MGRSoftWall NextGen is a dual-density foam for soft touch panels in aircraft cabins designed to reduce weight and deaden aircraft noise. Available in a wide range of finishes, shapes and patterns, the panels can be installed on seat shells, monuments and around sleeping areas. The company says the foam reduces the weight of soft touch cabin panels by up to 60% and its advanced quick-connect magnetic attachment system reduces maintenance time while allowing flexibility to refresh cabin design.

LVS100 Life Vest Pouch

Credit: Trenchard Aviation Group

Designed to cut down on life vest pouch search and inspection time mandated by the U.S. Transportation Security Administration, Trenchard Aviation Group’s LVS100 Life Vest Pouch simplifies the process of checking life vest pouches for seal tampering during flight turnarounds. LVS100 features an RFID device as a sealing option, so instead of physically removing vests from pouches during inspection, security personnel can walk through the aircraft with handheld meters that look for signal response from the RFID seals, which the company says cuts search and inspection time from several man-hours to minutes.

Collapsible Beds

Credit: Delft University

Designed for the Flying V aircraft currently in development at TU Delft, this seating concept features collapsible beds for economy class meant to effectively utilize the oval cabin space at the rear side of the wing. The design enables three passengers to lay down, with the middle bed being able to slide up while half of the bottom bed can fold down. The “triple bunk bed” can be converted into three seats for take-off and landing.

Flymingo Next

Credit: Moment

Flymingo Next from digital tech specialist Moment is an embedded IFEC system that synthesizes all onboard procedures into a single access point. Applications ranging from passenger entertainment to crew flight operations are controlled through hardware units consisting of a maximum of two components—a server/wireless application protocol (WAP) and a simple WAP. According to Moment, Flymingo Next ensures high inflight performance with Wi-Fi coverage, streaming speed and radio communications. Each of the units provides HD streaming to 100 passengers and Moment says they can be installed overnight in either overhead bins or the avionics bay.

F/List Vinyl Tile Flooring

Credit: F/List

Interiors specialist F/List has designed a tile-based vinyl flooring system for aircraft, which it says provides much more flexibility for custom flooring designs in business jets compared to previous methods that use vinyl flooring supplied in rolls. According to the company, the tile-based system enables easy installation and removal with the ability to replace single tiles, so maintenance and modification is simplified.

Coffee House Cabin

Credit: University of Cincinnati

This business traveler-focused cabin concept was developed by the University of Cincinnati in conjunction with the Live Well Collaborative. The concept entails center aircraft seating that can be converted into workstation space during flight, with space-efficient tables and retractable screens. During takeoff and landing, seats would rotate towards the front of the aircraft and table wings would fold down.

eSmartGalley

Credit: Diehl

Diehl’s eSmartGalley combines new cabin communication architectures and smart functions with “state-of-the-art galley technologies” to improve cabin crew operations and galley maintenance. Airlines could collect, process and transmit data for predictive health management and Diehl says remote maintenance functions would enable specialists on the ground to solve galley issues with minimal impact on cabin crew operations. These operations would be improved through a touch screen interface, digital inventory management and RFID-trolley detection.

A look at new cabin innovations that could provide improvements for aircraft cabin and component maintenance—plus a few interesting seating concepts.