Gallery: MHIRJ’s West Virginia Service Center Rolls Out MRO Innovations

Lindsay Bjerregaard July 09, 2024

Regional Maintenance Hub

First established in the early 1990s, MHIRJ’s West Virginia Service Center operates around the clock and focuses on heavy maintenance for regional carriers such as Endeavor Air, Piedmont Airlines and PSA Airlines. Aviation Week Network visited the facility to get a behind-the-scenes look at how MHIRJ is rolling out maintenance innovations and a unique training program.

Large Campus

Located in Bridgeport, West Virginia, the facility has around 200,000 ft.2 of hangar space and features seven maintenance bays, offices, back shops and classroom space. It currently has the capability for 16 lines of maintenance.

Expanding Capabilities

The West Virginia Service Center initially launched with services for Short C-23 Sherpa aircraft in the 1990s before becoming a hub for MHIRJ’s Bombardier CRJ maintenance services. MHI purchased the CRJ series aircraft program from Bombardier in 2020. In recent years, the MRO provider has expanded into more platform-agnostic MRO, landing deals to provide services for Embraer ERJ-145 aircraft and adding mobile-repair capability for the Airbus A220.

Back Shops

In addition to heavy maintenance checks, the facility offers a wide range of MRO capabilities such as interiors, non-destructive testing, welding, CNC machining, composite repairs, sheet metal, batteries and aircraft painting.

Paint Robot

MHIRJ employees designed and manufactured this robotic machine, which is used to paint large sections of an aircraft in the hangar. It recycles fumes so painting can take place safely in the hangar with no smell.

Robotic Tug

MHIRJ uses a robotic tug to help position aircraft, such as the one pictured here, more efficiently in hangars.

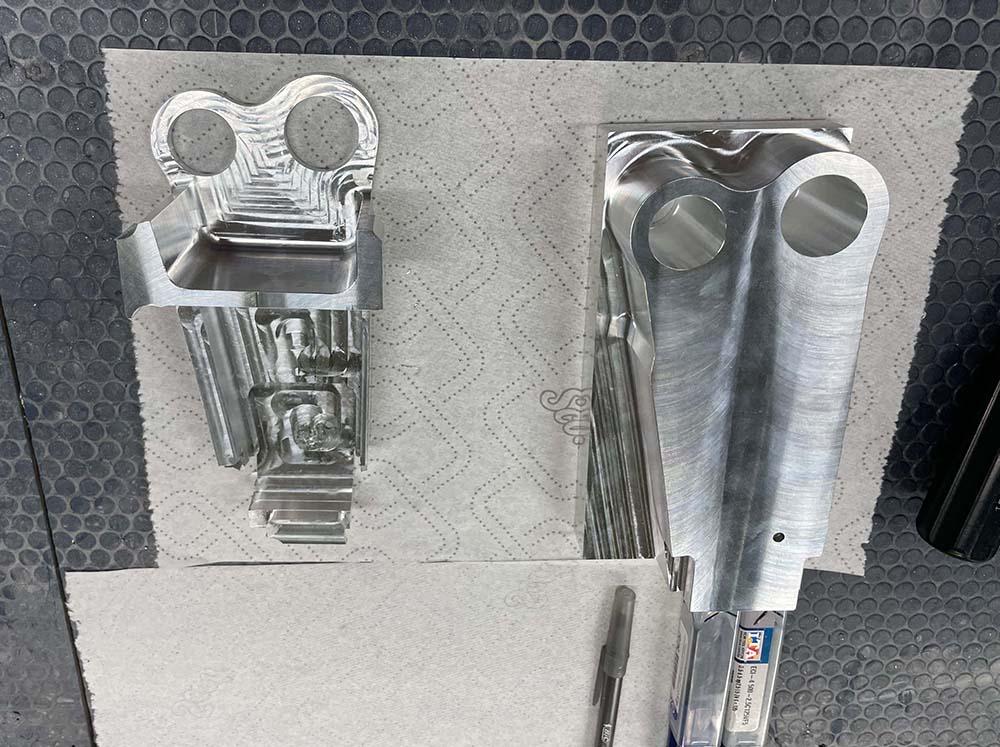

Manufacturing Parts

In 2023, MHIRJ added the capability to manufacture and certify parts in-house, which can either be put back on equipment or sold as new. The pictured parts were manufactured for an AOG situation.

Structure Work

During Aviation Week Network’s visit, structure work was taking place in this back shop on passenger doors.

Tool Tracking

These machines allow MHIRJ to keep track of tools as they are checked out and returned by technicians.

New Hangars

In 2022, MHIRJ completed the construction of two new hangars at the facility, which provide more than 100,000 ft.2 of additional hangar space and can accommodate Airbus A320-sized aircraft.

Modular Doors

The new hangars incorporate modular doors that can be opened independently. For example, in winter, if an aircraft needs to move in or out of the hangar, MHIRJ can open only the door on that side to prevent cold air from entering the entire hangar.

Modular Staging

MHIRJ is also using modular staging in the new hangars. Its size and height can be customized depending on which aircraft technicians are working.

Bay Of Excellence

One of the new hangars is serving as MHIRJ’s “Bay of Excellence,” where it is trialing new technologies and processes to drive greater efficiencies. According to MHIRJ President and Chief Operating Officer Ismail Mokabel, the concept is a merger between Japanese continuous improvement, American and Canadian ingenuity, and Lean principles to “help us unlock value from our MRO assets.”

Going Digital

One way in which MHIRJ is pursuing efficiencies in the Bay of Excellence is through digital technologies. The monitors pictured here are used to track projects, and the company is also in the process of going paperless by implementing EmpowerMX software, which technicians use on iPads.

Cleaner Footprint

A simple way MHIRJ made the new hangars more efficiency was by establishing rooms specifically dedicated to storing technician toolboxes, which frees up hangar floor space. “It seems like a simple thing, but it’s a big thing. It keeps everything clean, and cleanliness is happiness,” says Michael Genin, director of operations at the MHIRJ West Virginia Service Center.

Efficient Staging

Instead of hangar space cluttered by toolboxes, MHIRJ can now utilize that space for custom-built racks that are used to stage items more neatly and efficiently.

Workforce Growth

The West Virginia Service Center employs around 400 technicians, and MHIRJ plans to hire another 100 within the next year.

MHIRJ Academy

To boost workforce recruitment, MHIRJ recently established a new MHIRJ Academy at the facility to help people with technical skills from other industries transition to aviation. The tuition-free, eight-week program provides technical training for aviation sheet metal, during which participants are also paid.

Student Workstations

In addition to a computer lab, the academy has 20 workstations for students equipped with all the tools they will need for the course. MHIRJ is considering duplicating the program at its service center in Tucson, Arizona.

Graduation Day

MHIRJ Academy’s first graduation ceremony took place the day Aviation Week Network visited the West Virginia Service Center. There were 19 graduates in the first cohort, and demand for the program is strong—there are currently close to 400 applicants, thanks in part to word-of-mouth referrals by technicians already working at MHIRJ.

Aviation Week Network goes behind-the-scenes at MHIRJ's West Virginia Service Center to see how its "Bay of Excellence" and MHIRJ Academy programs are improving MRO operations and workforce recruitment.