Growing Capabilities

AI Engineering Services Limited (AIESL) has recently grown its MRO capabilities, becoming the first Indian maintenance provider to conduct a Boeing 737 MAX heavy check and inducting its first international customer aircraft in September 2023. Aviation Week got an exclusive look inside its Nagpur facility to see its engine and airframe maintenance capabilities firsthand.

Facility Overview

The Nagpur site has two hangar facilities, one engine shop, and one test cell for testing of GEnx and GE90 engines, which power Boeing 787 and 777 aircraft, respectively. It also features composite and structural shops, an oxygen bottle charging and pressure testing shop, a non-destructive testing shop and other facilities. Both hangars are approved by the FAA and India’s Directorate General of Civil Aviation to carry out major checks on Boeing 777 and Airbus A320 family aircraft.

First International Customer

During Aviation Week’s visit, a Kuwait Airways 777 was undergoing a heavy C check in one of the hangars. Marking a major milestone for AIESL, the aircraft is the facility’s first international customer to undergo a heavy check.

Planning For More International Business

In total, AIESL has inducted four Kuwait Airways 777s at the facility for C checks. AIESL expects more international customers in 2024.

Engine Test Cell

AIESL’s engine test cell includes automatic test equipment and a lab for testing fuel, oil and hydraulic fluids.

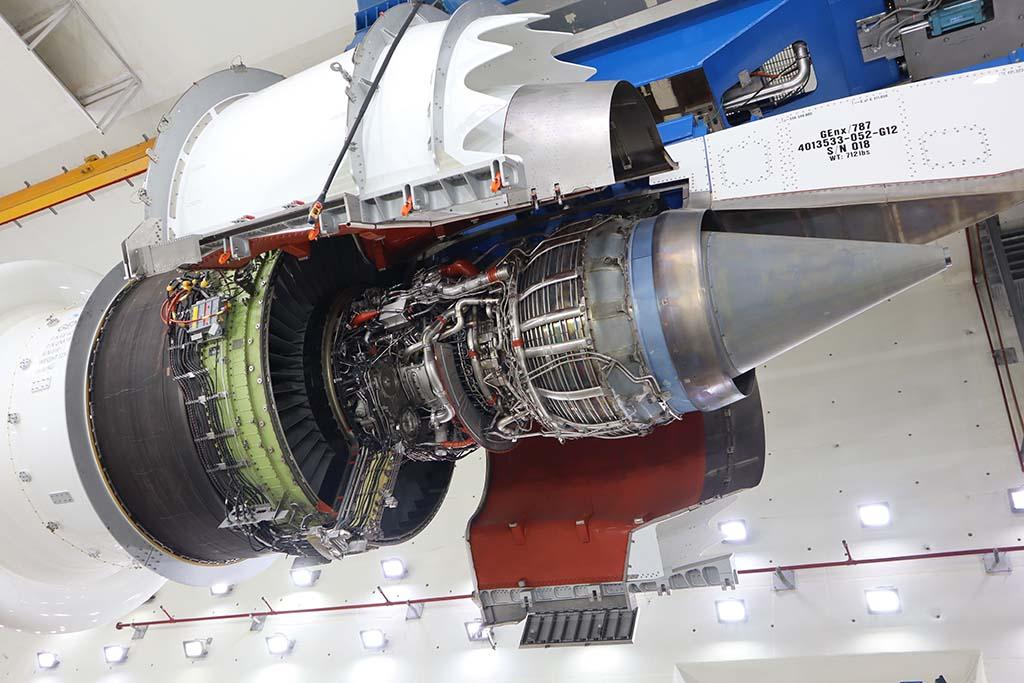

Engine Assembly

The GEnx-1B engine pictured here was being assembled in one of AIESL’s engine test cells. The sixth and seventh stages of the GEnx are made of titanium aluminide, which reduces the engine’s weight by about 400 lb. and increases fuel efficiency.

Testing Prep

A GEnx-1B engine being prepared for testing, including installation of a test adapter. AIESL performs regular checks and servicing of engine components—such as spark plugs, filters and oil levels—at the facility to help detect potential issues before they lead to malfunctions or failures.

Inside The Test Cell

A closer look at the test adapter installation in-progress on a GEnx-1B. The engine is installed on the test bed through the help of an engine handling system.

Testing A GEnx

Another angle of the GEnx-1B under testing. The test cell provides a controlled environment for testing engines.

Engine Test Control Center

AIESL monitors the engine testing process from inside this engine test control center.

Additional Engine Services

In addition to engine testing, the facility performs regular inspections, cleaning and maintenance of GEnX and GE90 engines.

A look inside aircraft maintenance and engine testing work at AIESL’s Nagpur facility.