Credit: Lindsay Bjerregaard/AWST

The Orbis Flying Eye Hospital has traveled to 97 countries to deliver sight-saving surgeries and ophthalmology training to middle- and low-income countries. In the past five years it has been used to complete more than 19.5 million eye screenings and examinations, more than 260,000 trainings, and more than 350,000 eye surgeries and laser procedures. Read on to find out more about how this unique aircraft has been converted into a dual classroom/hospital environment and how the Orbis maintenance crew keeps the aircraft flight ready.

The Orbis Flying Eye Hospital has traveled to 97 countries to deliver sight-saving surgeries and ophthalmology training to middle- and low-income countries. In the past five years it has been used to complete more than 19.5 million eye screenings and examinations, more than 260,000 trainings, and more than 350,000 eye surgeries and laser procedures. Read on to find out more about how this unique aircraft has been converted into a dual classroom/hospital environment and how the Orbis maintenance crew keeps the aircraft flight ready.

Creating A Flying Hospital

Credit: Lindsay Bjerregaard/AWST

The current, third-generation Orbis Flying Eye Hospital is a 1973 model McDonnell Douglas DC-10 that was converted to an MD-10 through a retrofit that updated its technology flight deck and makes it functionally identical to the MD-11. The new digital cockpit features avionics such as ADSB-in/-out, TCAS and all the systems required to fly anywhere in the world.

The current, third-generation Orbis Flying Eye Hospital is a 1973 model McDonnell Douglas DC-10 that was converted to an MD-10 through a retrofit that updated its technology flight deck and makes it functionally identical to the MD-11. The new digital cockpit features avionics such as ADSB-in/-out, TCAS and all the systems required to fly anywhere in the world.

The Hospital’s Former Life

Credit: Lindsay Bjerregaard/AWST

The aircraft previously served as a passenger-freighter combi aircraft which held the record in 1973 for the most amount of freight flown. FedEx purchased the aircraft in the 1980s and converted it to a full freighter before donating it to Orbis. According to Bruce Johnson, director of aircraft operations and maintenance at Orbis International, the aircraft is the oldest MD-10-30 still flying.

The aircraft previously served as a passenger-freighter combi aircraft which held the record in 1973 for the most amount of freight flown. FedEx purchased the aircraft in the 1980s and converted it to a full freighter before donating it to Orbis. According to Bruce Johnson, director of aircraft operations and maintenance at Orbis International, the aircraft is the oldest MD-10-30 still flying.

Simplifying the Design

Credit: Lindsay Bjerregaard/AWST

Orbis previously operated a DC-8 and a DC-10, both of which had STCs that made the hospital equipment part of the aircraft. The latest Orbis Flying Eye Hospital features a customized modular design where the hospital section is palletized, so it can be removed for easy maintenance. Later this year, the hospital section will be removed for the first time so Orbis can perform an inspection and make upgrades to components such as the aircraft’s water system.

Orbis previously operated a DC-8 and a DC-10, both of which had STCs that made the hospital equipment part of the aircraft. The latest Orbis Flying Eye Hospital features a customized modular design where the hospital section is palletized, so it can be removed for easy maintenance. Later this year, the hospital section will be removed for the first time so Orbis can perform an inspection and make upgrades to components such as the aircraft’s water system.

Ground Systems

Credit: Lindsay Bjerregaard/AWST

A normal MD-10 has one water tank, but the Flying Eye Hospital has six 60-gallon water tanks that go through three kinds of filtration—ultraviolet, charcoal and bromine—to kill every kind of bacteria known to man. The water is tested daily to make sure it is hospital grade.

In addition to its water system, the aircraft features a wide variety of ground systems to keep it running, including generators for power, a medical gas system and a liquid cooling system, which helps to keep the operating room between 68-72 deg. F. All the ground equipment is packed as freight during flight.

A normal MD-10 has one water tank, but the Flying Eye Hospital has six 60-gallon water tanks that go through three kinds of filtration—ultraviolet, charcoal and bromine—to kill every kind of bacteria known to man. The water is tested daily to make sure it is hospital grade.

In addition to its water system, the aircraft features a wide variety of ground systems to keep it running, including generators for power, a medical gas system and a liquid cooling system, which helps to keep the operating room between 68-72 deg. F. All the ground equipment is packed as freight during flight.

Powering a Hospital

Credit: Lindsay Bjerregaard/AWST

The hospital section is not actually connected to the aircraft’s APU. It features quadruple power backups, so in addition to the two generators that primarily power it, the aircraft also features an uninterruptible power supply and batteries within the hospital equipment itself. The generators run into a switching unit that prioritizes power, so if one generator quits, priority stays in the hospital section.

The hospital section is not actually connected to the aircraft’s APU. It features quadruple power backups, so in addition to the two generators that primarily power it, the aircraft also features an uninterruptible power supply and batteries within the hospital equipment itself. The generators run into a switching unit that prioritizes power, so if one generator quits, priority stays in the hospital section.

Credit: Lindsay Bjerregaard/AWST

The palletized hospital area is separated from the front of the aircraft with a 9G barrier for fire safety. The hospital portion is not operational during flight and no crew go beyond this barrier other than in cases of emergency. The crew is trained for firefighting capability and the aircraft has fire suits, goggles and other emergency equipment on board.

The palletized hospital area is separated from the front of the aircraft with a 9G barrier for fire safety. The hospital portion is not operational during flight and no crew go beyond this barrier other than in cases of emergency. The crew is trained for firefighting capability and the aircraft has fire suits, goggles and other emergency equipment on board.

Jack-of-All-Trades Maintenance Crew

Credit: Lindsay Bjerregaard/AWST

The three maintenance personnel that always fly with the aircraft do much more than just mechanic work. In addition to their firefighting training, they are trained as flight attendants and perform tasks such as coordination with ground crews and readying flight paperwork, weight and balance, and pre-flight checks.

The maintenance crew handles loading, unloading and connecting the vast amount of ground equipment powering the various hospital systems. According to Valerie Suberg, senior manager of aircraft maintenance at Orbis International, it takes approximately one day each to offload and re-pack all of the ground equipment.

The three maintenance personnel that always fly with the aircraft do much more than just mechanic work. In addition to their firefighting training, they are trained as flight attendants and perform tasks such as coordination with ground crews and readying flight paperwork, weight and balance, and pre-flight checks.

The maintenance crew handles loading, unloading and connecting the vast amount of ground equipment powering the various hospital systems. According to Valerie Suberg, senior manager of aircraft maintenance at Orbis International, it takes approximately one day each to offload and re-pack all of the ground equipment.

Handling AOGs in Remote Areas

Credit: Lindsay Bjerregaard/AWST

The Flying Eye Hospital flies to many remote areas of the world, so it does not always have access to an MRO partner in the case of an aircraft on ground situation. Suberg says Orbis’ maintenance crew is very self-sufficient and the aircraft carries its own spare parts, which are donated by FedEx. If the aircraft is at a station that has a FedEx facility, they can call them about supplying needed parts. Otherwise, since the aircraft’s programs are generally around three weeks long, the team is able to wait for needed parts.

The Flying Eye Hospital flies to many remote areas of the world, so it does not always have access to an MRO partner in the case of an aircraft on ground situation. Suberg says Orbis’ maintenance crew is very self-sufficient and the aircraft carries its own spare parts, which are donated by FedEx. If the aircraft is at a station that has a FedEx facility, they can call them about supplying needed parts. Otherwise, since the aircraft’s programs are generally around three weeks long, the team is able to wait for needed parts.

Handling AOGs in Remote Areas

Credit: Lindsay Bjerregaard/AWST

Suberg notes that since doctors and nurses come to the program every week, they can sometimes rely on medical professionals to bring needed parts. The aircraft has a minimum equipment list, so some things can also be deferred. Since Orbis’ traveling programs do not take place back-to-back, the team can re-supply afterward as necessary.

Suberg notes that since doctors and nurses come to the program every week, they can sometimes rely on medical professionals to bring needed parts. The aircraft has a minimum equipment list, so some things can also be deferred. Since Orbis’ traveling programs do not take place back-to-back, the team can re-supply afterward as necessary.

Mobile Maintenance Office

Credit: Lindsay Bjerregaard/AWST

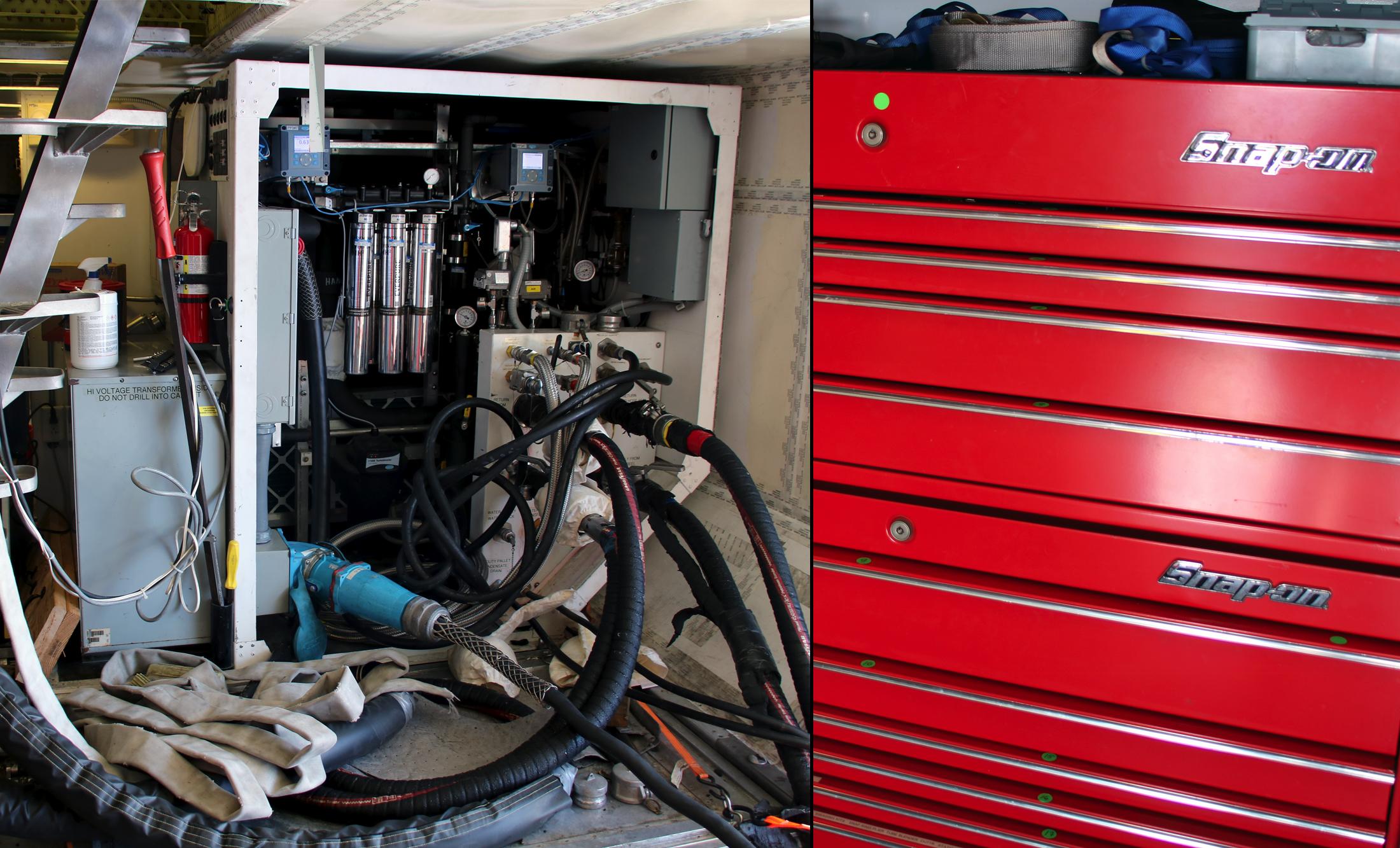

When the aircraft’s ground equipment has been unloaded, the cargo compartment it normally occupies is transformed into an aircraft maintenance and bio-med office. Maintenance crew monitor the aircraft’s systems and ground equipment, including levels of oxygen, fuel and electricity. Meanwhile, bio-med monitors everything in the hospital environment using the vast array of cameras installed on-board and in-house software.

The cargo compartment is also equipped with toolboxes donated by Snap-on and special lightweight stairs that can be broken into three pieces and stored inside.

When the aircraft’s ground equipment has been unloaded, the cargo compartment it normally occupies is transformed into an aircraft maintenance and bio-med office. Maintenance crew monitor the aircraft’s systems and ground equipment, including levels of oxygen, fuel and electricity. Meanwhile, bio-med monitors everything in the hospital environment using the vast array of cameras installed on-board and in-house software.

The cargo compartment is also equipped with toolboxes donated by Snap-on and special lightweight stairs that can be broken into three pieces and stored inside.

Maintenance Cycles

Credit: Orbis International

The aircraft logs approximately 100 flight hr. per year and lands approximately 25-30 times per year. Because the aircraft spends so much time on the ground in hospital mode, it is on a low utilization program that was configured by Boeing. Its maintenance program, which was put together with the help of Boeing and FedEx, is on a 24-month C-check cycle and a six-month A-check cycle. Orbis’ own maintenance staff performs the A-checks and the nonprofit uses a variety of global maintenance partners for C-checks, such as ST Aerospace, HAECO, AerSale and ComAv. “When it comes to big heavy maintenance—the primary structural elements—we’ll never hit another one on this airplane because of the way we fly,” notes Johnson.

The aircraft logs approximately 100 flight hr. per year and lands approximately 25-30 times per year. Because the aircraft spends so much time on the ground in hospital mode, it is on a low utilization program that was configured by Boeing. Its maintenance program, which was put together with the help of Boeing and FedEx, is on a 24-month C-check cycle and a six-month A-check cycle. Orbis’ own maintenance staff performs the A-checks and the nonprofit uses a variety of global maintenance partners for C-checks, such as ST Aerospace, HAECO, AerSale and ComAv. “When it comes to big heavy maintenance—the primary structural elements—we’ll never hit another one on this airplane because of the way we fly,” notes Johnson.

Special Maintenance Considerations

Credit: Lindsay Bjerregaard/AWST

Johnson says Orbis will only need to remove the hospital section every six years to enable structural inspections. “One of the things we did when we first put the hospital in is we realigned all those inspections on the interior that were structural,” he says. “We did every single one of them so we could maximize the time. We aligned them all so that we didn’t have them sporadically arranged.”

Since the Flying Eye Hospital doesn’t fly as much as a typical aircraft, Johnson says corrosion protection is of the utmost importance. However, the aircraft did not actually experience long-term storage procedures like many other aircraft during the pandemic. “Nobody knew when you were going back into action, so we actually kept it in flyable condition the entire time,” he says. “Every three weeks our group of mechanics would go down, run the engines, taxi the airplane and do all those kinds of things.”

Johnson says Orbis will only need to remove the hospital section every six years to enable structural inspections. “One of the things we did when we first put the hospital in is we realigned all those inspections on the interior that were structural,” he says. “We did every single one of them so we could maximize the time. We aligned them all so that we didn’t have them sporadically arranged.”

Since the Flying Eye Hospital doesn’t fly as much as a typical aircraft, Johnson says corrosion protection is of the utmost importance. However, the aircraft did not actually experience long-term storage procedures like many other aircraft during the pandemic. “Nobody knew when you were going back into action, so we actually kept it in flyable condition the entire time,” he says. “Every three weeks our group of mechanics would go down, run the engines, taxi the airplane and do all those kinds of things.”

Getting Back to Business

Credit: Lindsay Bjerregaard/AWST

Although the aircraft has not flown during the pandemic, Orbis continued its mission through its telemedicine platform, Cybersight. It completed 26,041 trainings, 746 patient consultations and 107 live webinars across 192 countries in 2020. The nonprofit is still monitoring the COVID-19 situation, but it hopes to get back into flight operations in 2022.

Although the aircraft has not flown during the pandemic, Orbis continued its mission through its telemedicine platform, Cybersight. It completed 26,041 trainings, 746 patient consultations and 107 live webinars across 192 countries in 2020. The nonprofit is still monitoring the COVID-19 situation, but it hopes to get back into flight operations in 2022.

A look inside the unique MD-10 aircraft conversion and how Orbis maintenance crews keep things running smoothly.