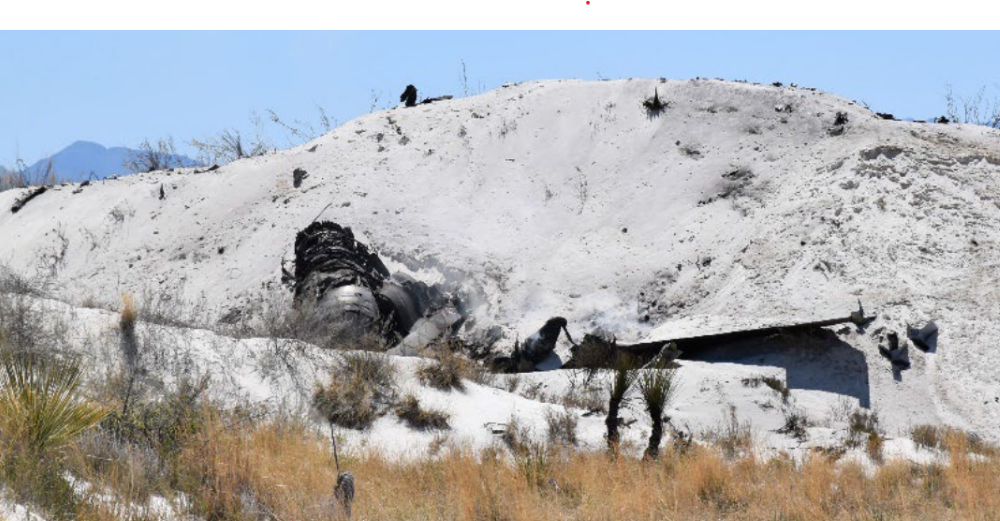

An F-16 engine, right-hand aft strake, horizontal tail and speed brake at the site of the April 2024 crash.

Credit: U.S. Air Force

Fan blade failure in a known “blind spot” of F-16 engine maintenance caused a Fighting Falcon to crash in New Mexico in 2024, a U.S. Air Force report says, prompting new questions on if inspection procedures should change for the aging fighter. The Block 42 F-16C, assigned to Holloman AFB, New...

Subscription Required

Failure In F-16 Engine ‘Blind Spot’ Caused Crash, Report Says is published in Aerospace Daily & Defense Report, an Aviation Week Intelligence Network (AWIN) Market Briefing and is included with your AWIN membership.

Already a member of AWIN or subscribe to Aerospace Daily & Defense Report through your company? Login with your existing email and password.

Not a member? Learn how you can access the market intelligence and data you need to stay abreast of what's happening in the aerospace and defense community.