When booking a pre-buy inspection, consider whether an aircraft is on the MRO's repair station certificate.

When considering a preowned business aircraft, the wise purchaser usually opts for a pre-buy inspection (PBI) to gain information about the aircraft’s condition. Also termed a pre-purchase evaluation (PPE) by some MROs, it presents an information resource for negotiating the aircraft’s final purchase price.

Though nearly all buyers of preowned aircraft opt for a pre-buy, securing a slot at an MRO could be a challenge, given the number of aircraft changing hands today. Jetnet data from Jan. 1 through Nov. 27, 2024, shows 1,834 business jets and 968 turboprops changed ownership.

To assure a pre-buy can be booked within a reasonable time frame, buyers should work with a verified broker, dealer or acquisition agent, and start engaging with a well-known, experienced MRO shop very early in the process, advises Phil Stearns, director of sales and marketing for Stevens Aerospace and Defense Systems.

“Most brokers and dealers [already] have deep relationships with many top-tier shops,” Stearns explains. “They keep an eye on predicted loading, especially during the fourth quarter when MROs are packed with normal work, and demand for PPIs is also very high. Even so, there are times when there is simply not enough time, space, capacity and technicians available to hit an end-of-year deadline at a given MRO, so [buyers] need to have other options lined up just in case.”

When considering a specific MRO, Stearns suggests ensuring a facility knows the aircraft type well, along with all the OEM/vendor warranty authorizations needed—and has a good industry reputation.

“The buyer should also want to know how many of this type of aircraft the MRO usually maintains, and how often,” he advises. “Does the MRO have full avionics, paint and interior capabilities in case they are needed? How many shifts are they running, and will the airplane be worked on during all of those shifts in order to expedite the PPE process? And what are the state tax implications of closing [the sale] on this airplane while it sits at the MRO?”

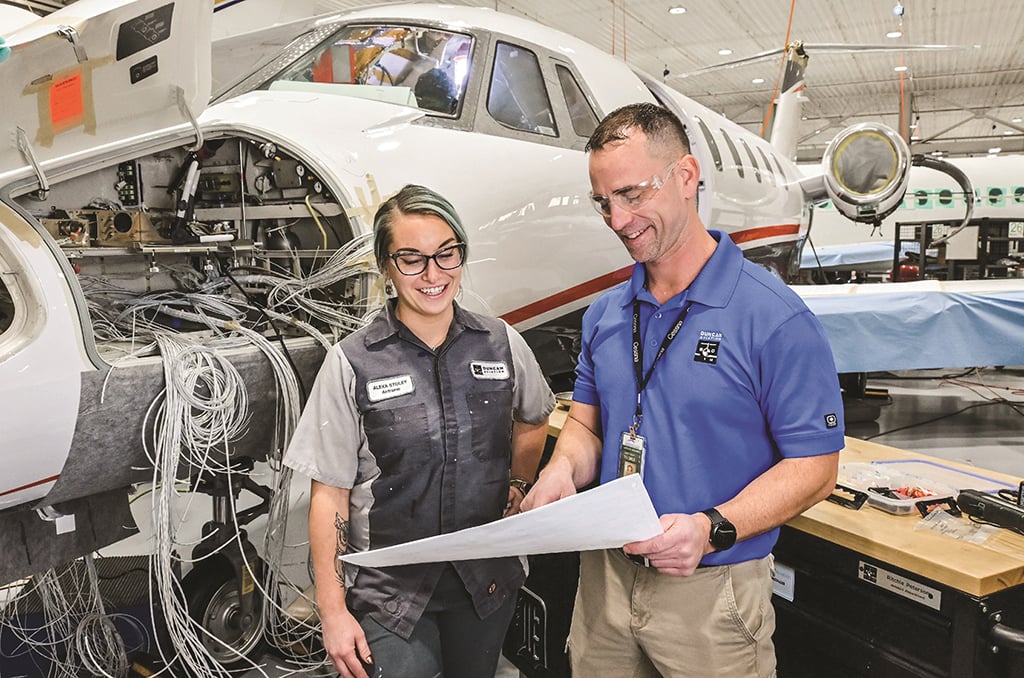

Because most MROs have strong backlogs, availability is a major factor when booking a PPE. Troy Nail, airframe and engine technical sales manager at Duncan Aviation, advises finding an MRO that has not previously maintained the aircraft because it is more likely that the shop will provide a neutral, unbiased evaluation of the aircraft. “If the shop has previously maintained the aircraft, there can be a bias due to previous relationships,” he cautions.

Casey Ritz, regional sales manager at Elliott Aviation. stresses that the MRO being considered should have the aircraft being booked for the PPI on its repair station certificate. “If it is on the certificate, the MRO will typically have factory-trained technicians, tooling and know what to look for,” he says. “Also, is there a dedicated project manager? If the answer is ‘no’ to any of these questions, it is best to look elsewhere,” he suggests.

John Ishaq, Part 135 director of maintenance at Clay Lacy Aviation, states that for most buyers, an OEM-authorized service center is the safest and most reliable option, especially for newer or high-value aircraft, because they ensure the inspection meets factory standards. Nonetheless, he says, an experienced independent MRO can be a cost-effective alternative, especially if the facility has specific expertise with the aircraft model. “But, regardless of choice, vet the MRO thoroughly and ensure the scope of the pre-buy aligns with your needs and the transaction requirements,” he says.

Planning Tips

To assure that, Ishaq urges the aircraft buyer to take an active role in the inspection process.

“Buyer involvement in the pre-buy process ensures a thorough evaluation, transparency and confidence in the aircraft’s condition,” he notes. “By attending key inspections, staying informed of progress and participating in discrepancy resolutions, the buyer can make informed decisions and negotiate effectively.” Leveraging experienced professionals to handle technical details ensures the process will be more efficient, he stresses.

Asked about how far in advance a pre-buy should be booked, Ishaq recommends 60-90 days. But he also points out that this time frame could extend to as much as 90-120 days when a complex or high-demand aircraft is involved, or during peak maintenance service periods. “Early engagement with the MRO and clear communication about your timeline and needs are essential to avoid delays in the acquisition process,” he stresses.

Elliott Aviation’s Ritz warns that a pre-buy inspection can be inherently difficult to plan, since the exact timing for the sale of an aircraft is not always predictable.

“A customer should engage an MRO even before the aircraft transaction has begun and communicate effectively with the MRO about scheduling and timing for the aircraft’s arrival to mitigate the risk of delaying an aircraft transaction and losing a slot,” Ritz says. “In some cases, a nonrefundable deposit can be utilized to ensure a slot remains available.”

Among the more efficient ways to secure time for a pre-buy is to have it performed in conjunction with a previously scheduled maintenance event. This can lead to cost savings, efficiency and a more thorough evaluation of the aircraft, says Clay Lacy Aviation’s Ishaq.

“It is especially advantageous for major inspections, aircraft approaching maintenance which is due or when the buyer wants a complete picture of the aircraft's condition,” he explains. “However, it (also) requires careful coordination, clear agreements with the seller and a well-defined inspection scope to ensure success.”

Along this line, Elliott Aviation’s Ritz says that the decision to fold in a PPI with a separate maintenance event really depends on the kind of event coming due.

“This should be discussed with the MRO facility to ensure it makes sense,” Ritz says. “If the scheduled maintenance event is due around the time of aircraft input, there could be some advantages with completing that event, but not eliminating the standard pre-buy inspection completely. Adding a scheduled maintenance event to a pre-buy inspection will allow for some labor savings and the added benefit of getting a repair station sign-off at the end of the inspection. This can provide more value to the customer.”

Greg Petersen, chief operating officer of Solairus Aviation, a California-headquartered aircraft management firm and charter operator, says that when scheduled aircraft maintenance is coming due, especially heavy checks such as a C-check on a Falcon, it is advisable to negotiate its completion into a pre-buy.

“While that inspection may not hit every item you want to inspect, it will hit a lot of them, and you kill two birds with one stone,” he explains. “Major areas of concern for any airframe should be included, if, for example, you are buying an airplane with a known corrosion problem in a certain area—as well as items with very high replacement costs.”

One industry expert, who asked to remain on background, cites mixed feelings on combining scheduled maintenance with a PBI.

“A pre-buy inspection is typically a near-term item. It needs to fit into the cadence of a transaction process, rather than a maintenance schedule,” he explains. “Accordingly, most pre-buy inspections won’t perfectly coincide with a scheduled maintenance event. However, it may make sense to do so if nearby MRO slot availability is a concern and the timing can align.”